World’s Largest Electronics Manufacturer Foxconn Wants 1 Million More Robots In 3 Years. Bye-bye Human Labor

Share

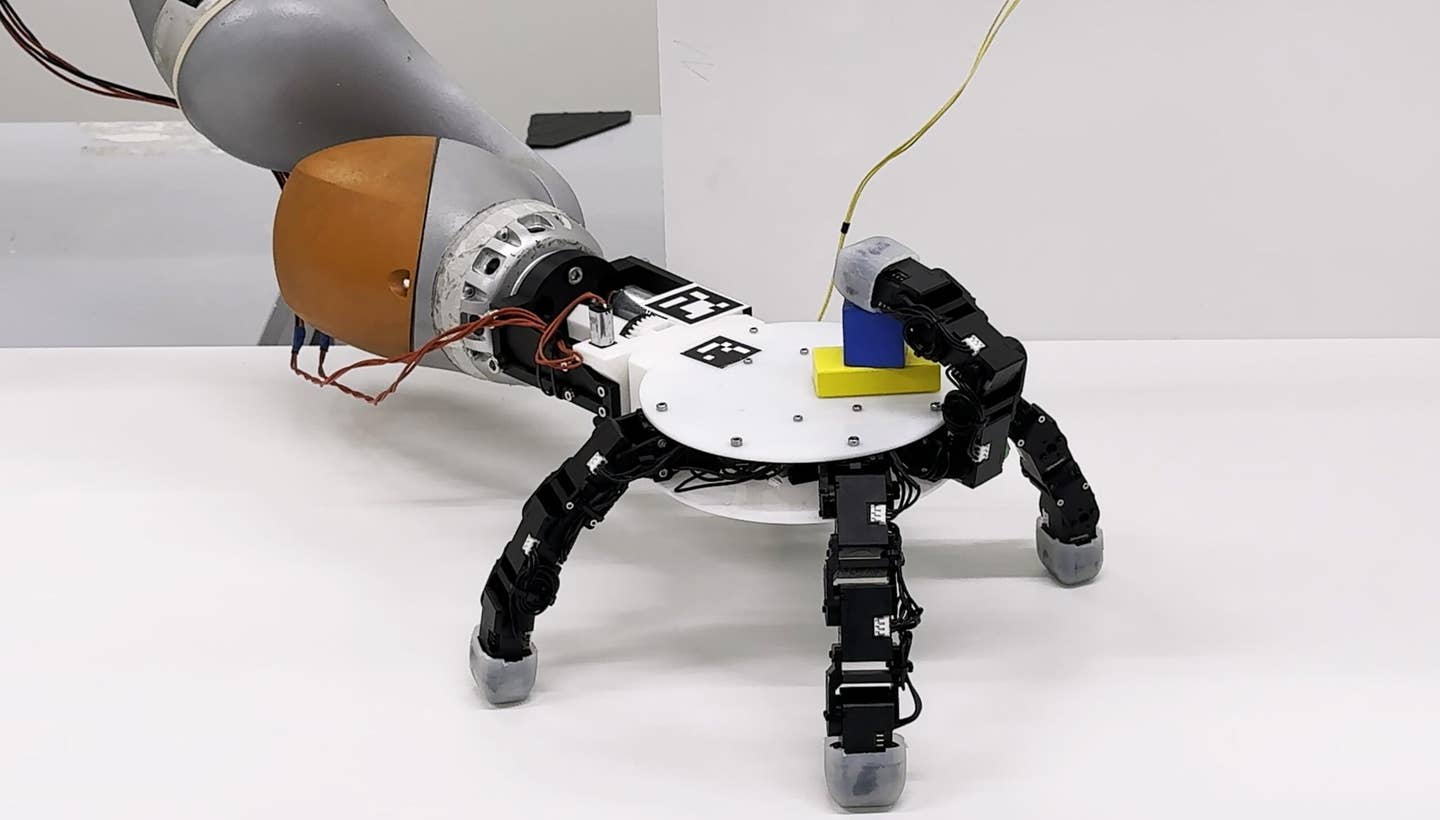

Cheap labor isn't cheap enough for the world's largest electronics manufacturer. Terry Gou, the CEO of Foxconn recently told employees that they would be replacing human workers with one million robots over the next three years. These robots would handle many basic manufacturing tasks such as spraying, welding, and assembly. Foxconn is based in Taiwan and has nearly 1.2 million workers, the vast majority of which (~1M) live in China, but it's unclear how many humans would be losing their positions during the switch. Even if robots are used to augment production rather than completely replace people, we're looking at a major shift in the industry. Contracted with Apple (it's rumored Foxconn makes the iPad2), HP, Dell, Nokia, Sony, and many other top brands, the electronics giant is singlehandedly responsible for nearly half of all such technological production in the world! If Foxconn switches from cheap Chinese labor to robots, can the rest of the world be far behind?

According to Xinhua News, Gou's comment was made at a company dance party last week. (Way to kill the mood, Gou.) Without a formal press announcement, it's unclear how drastic the cuts in human labor will be, though Gou said the move was intened to "replace some of its workers with 1 million robots in three years to cut rising labor expenses and improve efficiency."

Those rising labor expenses come in the form of bad press as well as actual financial costs. Since 2010, the world news outlets have been reporting on a 'rash' of suicides among Foxconn's Chinese workers, supposedly due to harsh conditions, long hours, and low pay. Last year, Gou announced that the number of suicides (roughly 18 in 2010 alone) were well within the statistical expectations for the company (as compared to general rates among the Chinese populace). Continued tragedies surrounding Foxconn's factories in China, however, continue to link the electronics giant to poor labor practices, as this more recent IDG news clip attests:

Terry Gou's recent announcement, then, may be a political statement as much as a business plan. Tell us our working conditions are too harsh on people...well then we'll just remove the people. Howda you like dem Apple(iPad2)s?

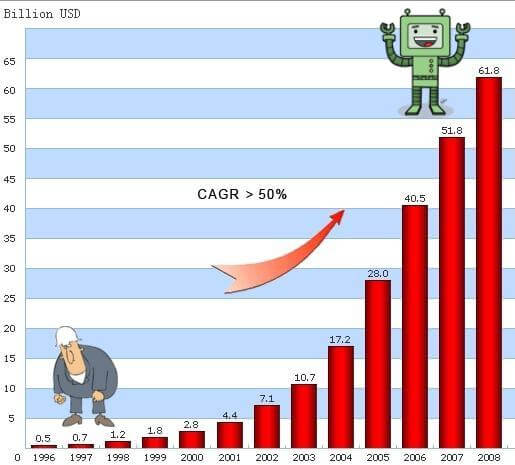

No matter their rationale, the shift in workers is a gargantuan overhaul. Currently Foxconn only has around 10,000 factory robots in use, but somehow plans to increase that figure to 300,000 during 2012 and up to 1 million in 2014. That seems like a herculean task, though not impossible. Foxconn has also already announced plans to increase mainland China workers to about 1.3 million by year's end. If both projections are correct, it looks like Foxconn will be growing in both human and robot workers, or perhaps using traditional labor as they continue to increase their automation. Either way, the company clearly means to stay at the top of the global electronics market.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

Finding the cheapest and most efficient labor has always been one of the key ingredients of success in manufacturing, so if Foxconn is aiming to replace or augment its workforce with a roughly equivalent number of machines in just three years, it's a good indicator that the world as a whole may be moving in that direction. We've certainly seen many examples of modern factories where automation has removed a great majority of human workers from the floor, and even cheap labor markets will often see machines and humans working side by side to increase efficiency. As Foxconn follows through on their three year plan, they'll give the world insight into the best ratio of man to machine to optimize production. Foxconn may add 1 million robots, but still keep the majority of its large human workforce and use the massive increase in output to keep up with the equally massive global demand for cheap electronics.

Yet whatever ratio of human/robot labor Foxconn adopts, you can bet that in the long run the percentage of people in production is only going to decline. As machines become more sophisticated, and associated costs of humans (medical expenses, lawsuits, etc) continue to rise, robots will make more sense for a great many repetitive tasks. In essence, the world's largest electronics manufacturer may have essentially declared the beginning of the end for human labor in the factory.

What will that mean in the years ahead? It's possible, as US robot makers have maintained recently, that the shift towards automation will bring employment back to post-industrial nations in the form of higher-end jobs. It's also possible (perhaps likely) that citizens may struggle during the transition from human to robot labor even as economies thrive, leading us to more "jobless recoveries". Martin Ford, in his book The Lights in the Tunnel, argues that the move to a robot based economy will ultimately require enormous shifts in government and economics as the majority of humanity no longer performs what could be traditionally called 'work'.

All of that, however, is purely speculation. What is certain is that Foxconn will do everything in its power to keep providing cheaper electronics to the world's leading brands. In the near term, that just means more inexpensive computers and mobile phones. Hopefully, however, this announcement will fuel a more public and substantive debate on the importance of automation. Media coverage in traditional news outlets has been disappointingly short sighted and uninspiring when it comes to facing the (possible) crisis that global adoption of automation may create. This is a topic that effects us all. While factories were among the first to become automated, law firms, news agencies, call centers, and dozens of other industries will soon be replacing/augmenting human labor with AI software. We need to be asking ourselves tough questions: How do we make that transition as painless as possible? What can we do now to lay down the foundation for future generations where the majority of work is automated? Where should we invest our capital to ensure the best returns when robots finally rule the world?

...if you have an answer to the last one, let me know.

[video credit: IDG News]

[source: Xinhua Net]

Related Articles

This ‘Machine Eye’ Could Give Robots Superhuman Reflexes

Scientists Send Secure Quantum Keys Over 62 Miles of Fiber—Without Trusted Devices

This Robotic Hand Detaches and Skitters About Like Thing From ‘The Addams Family’

What we’re reading