Augmented Reality To Help Military Mechanics Fix Vehicles (Video)

Share

The days when you can fix your own car may be coming to an end. New vehicles have complex onboard computerized systems densely packed under the hood. Mechanics face an ever climbing learning curve to keep up with advancing automotive technology. Luckily, developers at Columbia University's Computer Graphics and User Interface Lab have created a system that guides you as you make repairs. ARMAR, or Augmented Reality for Maintenance and Repair, is a head mounted display unit that provides graphic overlays to assist you in making repairs. An Android phone provides an interface to control the graphics you view during the process. Published in IEEE, and recently tested with the United States Marine Corps on an armored turret, ARMAR can cut maintenance times in half by guiding users to the damaged area and displaying 3D animations to demonstrate the appropriate tools and techniques. If successful in military applications, ARMAR may one day make it to the civilian market and provide a means for (amateur?) mechanics to keep all kinds of vehicles running for years to come. We've got a demonstration video from Columbia after the break.

Augmented Reality (AR) has seen a growing number of applications in the last year. Generally we've seen these applications in entertainment and map enhancements. ARMAR is a somewhat rarer breed of AR, focused on a specialized functional task. Such AR guidance could be expanded into all manner of assembly, maintenance, and repair jobs for computers, robotics, or any other electro-mechanical system. Such programs are effectively teaching as well as guiding the user, so perhaps we could see such techniques change the field of education. Students could "see" the insides of an atom in chemistry class, or browse through selections of artwork while reading about folk movements in history class. ARMAR demonstrates that AR could change more than the way we find restaurants or play video games. It could be the new lens through which we view our world.

ARMAR is the project of Prof. Steven Feiner and his student Steve Henderson at Columbia University. In the Marine Corps tests, the pair of researchers used 10 cameras in the vehicle to track three IR lights on the head mounted display (HMD). This tracking allows ARMAR to lead users to the target area and demonstrate the appropriate repairs needed in the current field of vision. ARMAR improved the efficiency of repairs when compared to an untracked HMD (56% faster) and a stationary LCD screen (47% faster) which provided similar information. The ARMAR team is looking to improve future models of the device by incorporating the viewing cameras onto the HMD, allowing it to function autonomously and with less setup.

Feiner and Henderson have also experimented with rudimentary haptic feedback by using the repair environment as a platform for projecting control buttons. Termed "opportunistic controls" this system turns different surfaces (metal bumps, a rotating connector, etc) into virtual knobs and switches you can feel. Their recent paper in IEEE highlights some of the advantages of such controls including no-look adjustments, increased user certainty, and allowing adjustments while keeping hands in the workspace. The following video demonstrates opportunistic controls (you only have to watch the first minute or so to understand the concept).

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

In the US, a good deal of technology makes it way to civilian use after first being vetted and improved by the military. I'm not certain how long it will take for an ARMAR like system to be economically feasible in the general automotive market. Military mechanics have to repair a variety of diverse machines, and thus ARMAR provides useful assistance when an individual does not have years of expertise in a particular vehicle. Private mechanics are unlikely to face similar situations until they must work on diesel, biofuel, hybrid, and electric cars all in the same shop.

That time, of course, is approaching rapidly. As object recognition and artificial intelligence improve, programs like ARMAR could become the definitive guides to helping humans maintain their mechanical world. Who knows, we may all eventually have HMDs in our homes to help us program the DVR or fix the high speed internet modem. Each device could come with software based instructions instead of paper manuals. Augmented Reality could finally allow me to assemble that coffee table/dish-drying rack from IKEA. Tell me ARMAR, which of these is a klippan and how do I attach it to the julfrid?

[photo and video credits: Steven Feiner and Steve Henderson, Columbia University]

Related Articles

This Light-Powered AI Chip Is 100x Faster Than a Top Nvidia GPU

How Scientists Are Growing Computers From Human Brain Cells—and Why They Want to Keep Doing It

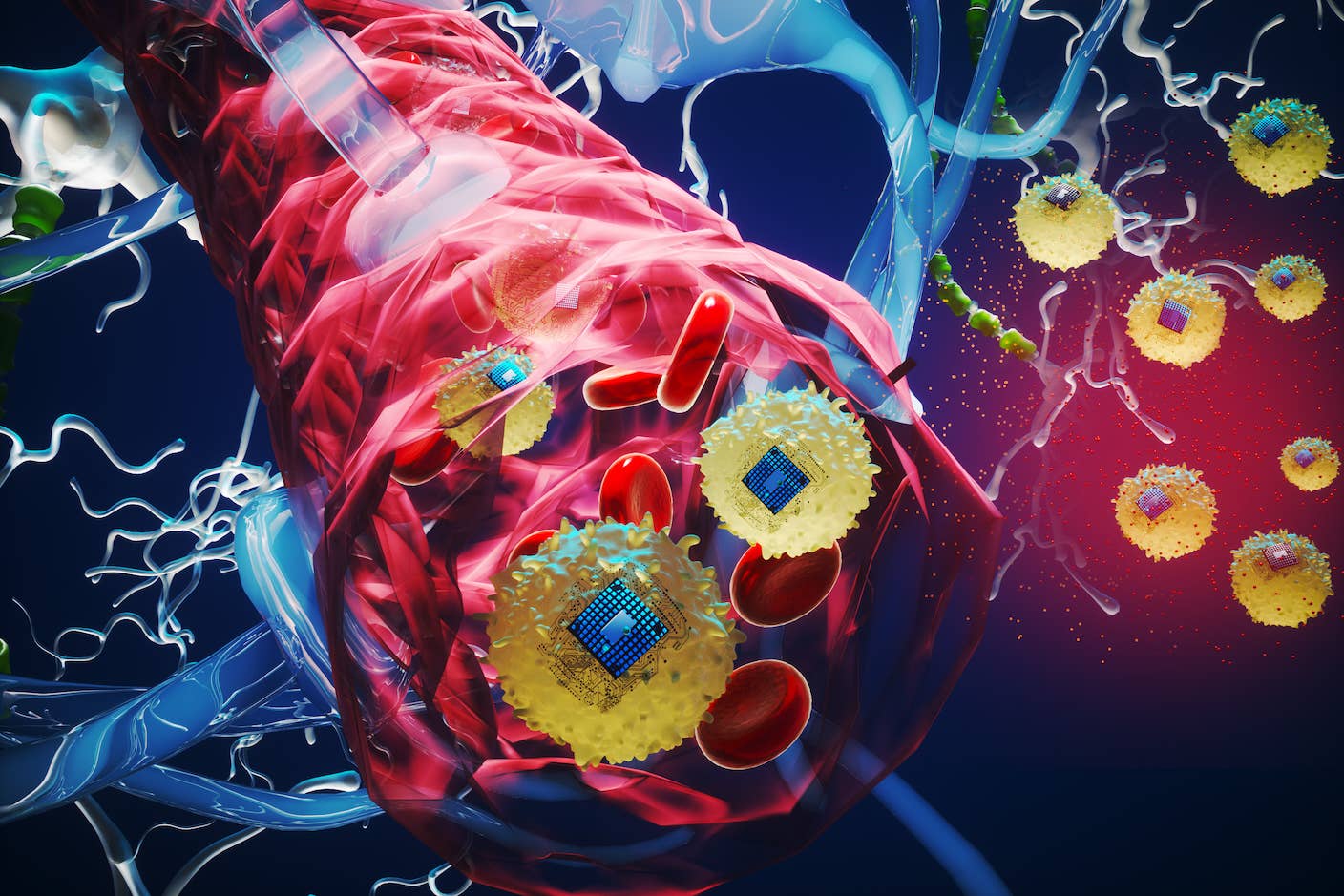

These Brain Implants Are Smaller Than Cells and Can Be Injected Into Veins

What we’re reading