Human Vs. Robot: Bricklaying Robot Can Place 1,000 Bricks an Hour

Share

Building houses of brick is almost as old as human civilization itself, and over the millennia, we’ve perfected the art. The fastest bricklayers can mortar and place over 700 bricks an hour. Pretty fast.

But a new robot can lay bricks even faster.

Mark Pivac, inventor of the bricklaying robot, Hadrian, told PerthNow that his bot can place 1,000 bricks an hour, enough to erect the walls of a house in two days of round-the-clock work—a task that, on average, takes a human crew four to six weeks of hard labor.

The robot works a little like a 3D printer, similarly taking its cues from a digital 3D model of the structure it’s building. Instead of extruding plastic or sintering metal, it cuts bricks to size, mortars them, and precisely lays each in place using a grasper at the end of a 28 meter telescopic boom.

Hadrian took ten years and $7 million to develop.

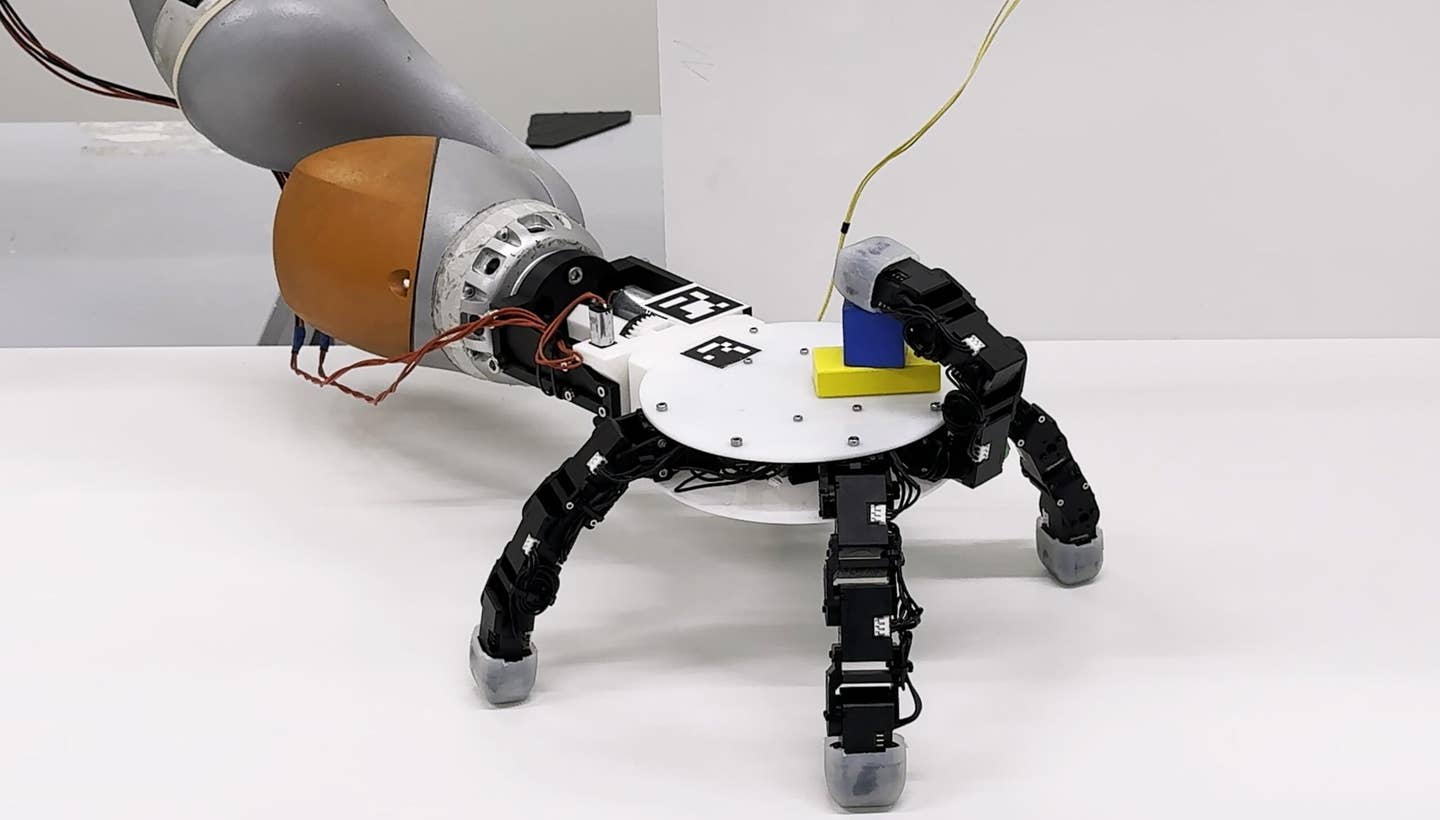

Perhaps unsurprisingly, however, Hadrian isn’t alone. We found another bricklaying robot, SAM by Construction Robotics, is also hard at work building walls of brick.

SAM isn’t as fast Hadrian. It currently tops out at a brick every 12 seconds or about 300 bricks per hour. The robot requires three human handlers: an operator, a tender to keep it supplied with bricks and mortar, and a mason to clean up and fine tune things after the robot passes. It builds the wall by advancing along a track—whereas Hadrian’s long, telescoping arm allows it build from a fixed point.

Getting the robot even this far was no small feat.

"The human brain is incredible and it's challenging to replicate accurately what a bricklayer does," says Nathan Podkaminer, Construction Robotics cofounder. "A human bricklayer adjusts instantaneously for wind, other workers on the scaffold and other conditions. It took us two years just to perfect SAM's ability to extrude mortar onto a brick."

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

In contrast with a human bricklayer, SAM mortars the brick itself before placing it on the wall. It uses a laser to correct for vibration and movement on the worksite, allowing it to place each brick with precision. (Check out some of the fastest human bricklayers in action below.)

According to Podkaminer, the system was never intended to completely replace humans. Rather, it was designed to augment them. Both Pivac and Podkaminer point to a shortage of bricklayers in the industry as the inspiration behind their work.

“We have absolutely nothing against bricklayers,” Pivac says. “The problem is the average age of bricklayers is going up and it’s difficult to attract new young people to the trade.”

There’s a debate on about the future of automation—what it means that machines may be able to match humans at virtually any task. For now, robots are nowhere near that advanced.

Bricklaying, however, is a good example of a task that lies somewhere in between the precisely controlled environment of a factory floor and the unpredictable environments most humans navigate every day—perfect for the incoming generation of bots.

Image Credit: Construction Robotics

Jason is editorial director at SingularityHub. He researched and wrote about finance and economics before moving on to science and technology. He's curious about pretty much everything, but especially loves learning about and sharing big ideas and advances in artificial intelligence, computing, robotics, biotech, neuroscience, and space.

Related Articles

This ‘Machine Eye’ Could Give Robots Superhuman Reflexes

This Robotic Hand Detaches and Skitters About Like Thing From ‘The Addams Family’

Waymo Closes in on Uber and Lyft Prices, as More Riders Say They Trust Robotaxis

What we’re reading