Look Out Humans – This FRIDA Robot From ABB Will Take Your Factory Job

Share

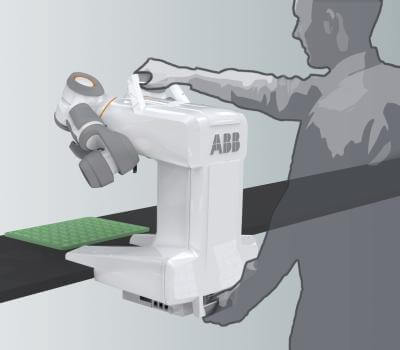

If a human worker can do it, why not a robot? Swiss robotics giant ABB recently unveiled a new concept robot that showcases how the company is aiming to have humanoid machines work side by side with people in manufacturing environments. FRIDA is a headless torso with two arms, each with seven degrees of freedom and a wide range of motion. Roughly the size of a small human, FRIDA can perform many of the same tasks as a two-armed person, yet its servos are gentle enough, and its sensors smart enough, to keep it from causing injury to any biological coworkers that run into it. Check out the robot's capabilities in the demo video below, followed by some great pics. While it's still only a concept piece, there's little doubt that robots like FRIDA could replace many of the remaining human workers in factories. The only question is if/when these robots will be available and cheap enough to be purchased by small scale manufacturers around the world.

FRIDA, which stands for Friendly Robot for Industrial Dual-arm Assembly, represents what most industrial robots aren't: light weight, padded, adaptable to multiple assembly lines, human-safe, human-sized, human-shaped, and (supposedly) inexpensive. ABB's strategy seems to be to make FRIDA as human as possible. It has the same basic shape and range as a small adult, the same number of degrees of freedom in its arms, and can be connected to vision cameras to give it optical awareness as well. This theme continues into aesthetics. Most ABB arm robots are big and orange to signal their danger to passing humans. FRIDA was purposefully designed to be light colored and approachable.

Rather than custom installations, each FRIDA would be able to fit into new situations as your business required. Sort of the industrial robotics equivalent of a wild card. ABB claims that, "normally, no safeguarding or enclosing of any kind is required, which allows for very fast installation, commissioning and relocation." According to ABB's concept, you could pick FRIDA up, move it to a station, get it to perform a task and then move it to a different station to complete other work. A single robot with multiple applications around the factory, or a fleet of such robots at your disposal - it's up to you. And because it can operate alongside humans without injury, factory owners can find ways of combining human and robot labor in the same workspace - dropping in machines as human replacements where possible without having to convert the entire line.

This new approach is suited to the areas where traditional industrial robotics have yet to infiltrate: low-capital small scale manufacturers whose products are labor intensive and not easily automated at every stage. (There's also possibilities in large capital endeavors that still require human labor - like memory card assembly.) If FRIDA can successfully conquer this niche it will be opening up a huge number of new businesses (or parts of businesses) to automation, which is why it's so understandable that ABB is pursuing this avenue of research. As we've discussed before, it seems like Rodney Brooks is aiming for the same niche with his new company, Heartland Robotics.

Of course, it's still not clear which company will be the first to move beyond concepts and promises to an actual robot that any business can buy. FRIDA is a great concept, but hasn't gone beyond the pilot phase. In these trials ABB admits that "tray handling and bin picking remain challenging operations for the robot." In other words, it's not a one-to-one replacement for humans even in stereotypical repetitive tasks. While ABB claims FRIDA will be easily programmable and adaptable to new situations, they haven't given any details as to how that programming will actually work. Will it require a laptop, or could you simply show the robot what to do? We also have no idea about what the final price for FRIDA will be. Until ABB clears up these questions there's no telling if FRIDA will be a new industry defining standard or a flop.

Yet I'm very certain that robots will continue to infiltrate all levels of manufacturing. Human labor is relatively expensive compared to the long term costs of automation, even in historically cheap labor markets like Asia and South America. Any task that is repetitive is essentially up for grabs, and it's only a matter of time until robots get cheap and smart enough to take up those tasks. While ABB, and the robotics industry as a whole, sees this progress as job creating and economically positive (by increasing productivity and keeping manufacturing local), the debate over automation rages on. Rightfully so. Take a good look at FRIDA in the pictures below. No head, just a pair of smart arms that can do things over and over again without stopping. To many businesses that's the perfect assembly line worker.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

Related Articles

These Robots Are the Size of Single Cells and Cost Just a Penny Apiece

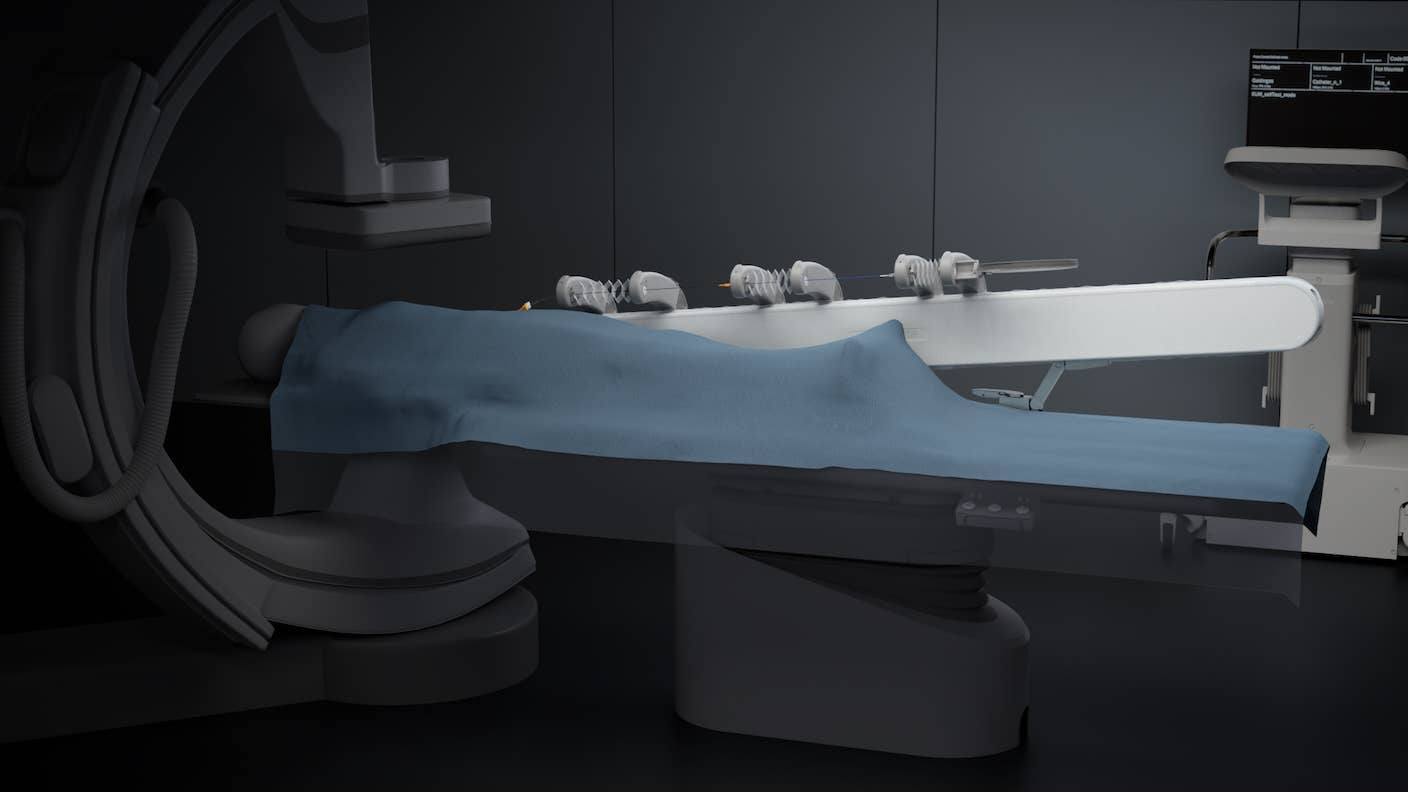

In Wild Experiment, Surgeon Uses Robot to Remove Blood Clot in Brain 4,000 Miles Away

A Squishy New Robotic ‘Eye’ Automatically Focuses Like Our Own

What we’re reading