Better, Faster, and Cheaper – These Robots Are Invading Car Manufacturing Plants

Share

Does anyone doubt that it really is just a matter of time before human assembly line workers are a thing of the past? And automakers are doing their best to gain a competitive edge by robotizing their manufacturing plants. Here’s a glimpse of some of the robots that have recently stepped onto the assembly line floor.

When Ford’s 2013 Escape hits the road later this year, it’s a safe bet that no one will notice just how precisely it’s parts are put together, compared to past models. The improved assemblage is due to a group of robots which use lasers and cameras to fit windshields, door panels, and fenders together more closely. When installing a windshield, a robot deposits adhesive evenly around the glass border, then uses a suction cup to move and secure it. Gaps between pieces are smaller, which makes for a more aerodynamic and quieter ride due to decreased wind noise.

The 2013 Escape is their first US-manufactured car to benefit from the seeing-eye robots. Ford had already been using the robots at their manufacturing plants in Europe but only recently installed 700 of them at their Louisville, Kentucky plant. The robots raise the quality of assembly to “custom-like build,” Ford engineer Thomas Burns said in a press release. The robots also give a boost to the all important bottom line by saving energy and reducing the physical strain exerted by their human co-workers.

And if you have laser-vision robots, you might as well use them to inspect their own handiwork. Check out Ford’s incredible robots in the following video. You can almost sense an awareness behind their scrutinizing inspection.

Ford cars will also have nicer coats to show off their improved assembly. The company is bringing 88 new robots to apply paint and sealer to vehicles. By getting rid of all the humans in paint zones the plant saves money by minimizing the need for climate and air current control.

And Ford isn’t completely automation-centric with their robotic upgrades. Last year the company bought robotic arms that turn their assembly workers into ergonomic cyborgs. Made by Equipois Inc., the X-Ar arms are wearable exoskeletons that bear the weight of the workers’ arms as they repeatedly grab small objects and assemble them. The X-Ars not only reduce fatigue and risk of ergonomic injury, but they increase manual dexterity and, ultimately, productivity.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

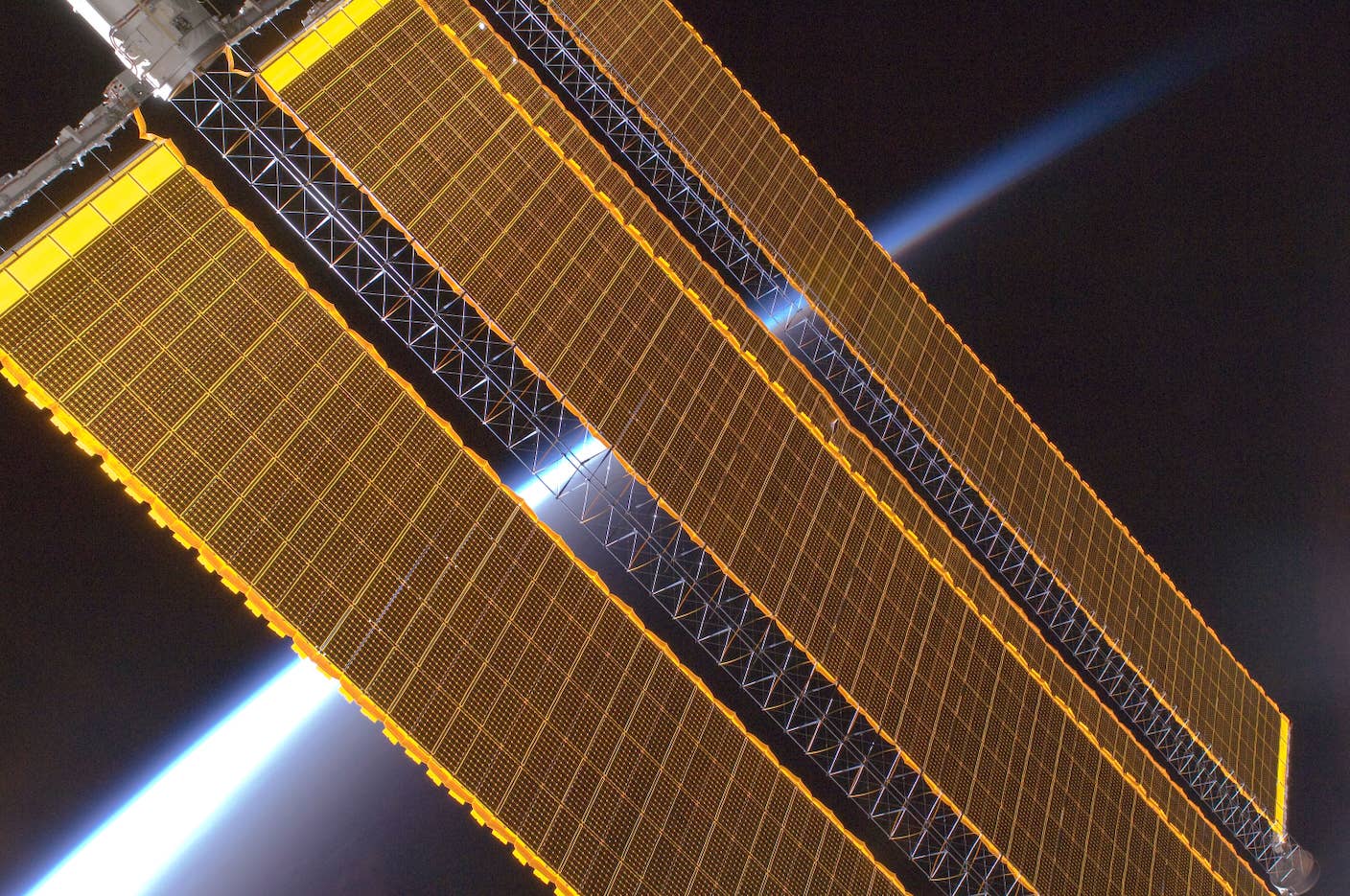

GM is doing their part to keep up with their competitors by adopting their own robotic appendage. With the help of NASA, the carmaker developed a robotic glove that, like the X-Ar, reduces the stress of repetitive motions on the assembly line. The so-called Human Grasp Assist Device, or Robo-Glove, is still a prototype. The arm comes with sensors, actuators, and simulated nerves, muscles and tendons that give its wearers an additional 10 pounds of bionic grip force while using tools. Robo-Glove is a spinoff of NASA’s humanoid robot, Robonaut 2, that is a permanent member of the International Space Station crew lending a helping hand with dangerous or mundane tasks.

Always at the forefront of increased efficiency through technology, China opened an automotive plant last August in Tianjin that is perhaps the most advanced in the world. The plant, belonging to Chinese automaker Great Wall Motors, has 30 workstations occupied by 27 robots that perform more than 4,000 high-precision welding operations. The robots are so fast they can complete the welding of an entire Haval SUV in just 86 seconds.

On the assembly line, more than many other places, time is money.

The master welders are actually a team of two types of robot, the IRB 6640 and IRB 7600, made by Swedish-Swiss robotics giant ABB Robotics. The IRB 7600 acts as the 6640’s assistant, holding panels and other equipment in place while IRB 6640 welds the parts together. The IRB 6640 is packing servo-driven welding guns which are 25 percent faster than traditional, pneumatic welding guns. What’s more, the robots are flexible enough to weld different car models.

Of course, automanufacturing plants aren’t the only ones being taken over by robots. Right now there are over 190,000 ABB robots in automotive factories worldwide, and last year ABB unveiled FRIDA, the two-armed, headless concept robot that’s meant to do what human assembly line workers can to, but do it better. FRIDA’s small size and 7 degrees-of-freedom arms makes for easy installation and flexibility to do whatever a particular manufacturing plant needs it to do.

Up 30 percent from 2010, robot sales exceeded all expectations last year, according to the International Federation of Robotics. Increased demand from places like China, where manufacturing is expanding, and lowered costs make it easier and more sensible for companies to replace their human workers with robotic ones. Maybe we should stop worrying about the robot apocalypse and start worrying about the human apocalypse that could result from so many factory workers out of the job.

Peter Murray was born in Boston in 1973. He earned a PhD in neuroscience at the University of Maryland, Baltimore studying gene expression in the neocortex. Following his dissertation work he spent three years as a post-doctoral fellow at the same university studying brain mechanisms of pain and motor control. He completed a collection of short stories in 2010 and has been writing for Singularity Hub since March 2011.

Related Articles

Data Centers in Space: Will 2027 Really Be the Year AI Goes to Orbit?

These Robots Are the Size of Single Cells and Cost Just a Penny Apiece

Hugging Face Says AI Models With Reasoning Use 30x More Energy on Average

What we’re reading