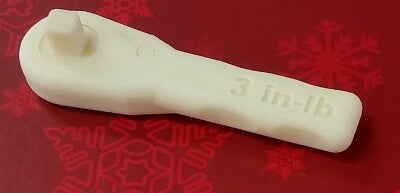

The Story Behind the First 3D Printed Wrench in Space [Video]

Share

You may recall that late last year, a breakthrough in manufacturing occurred a few hundred miles above the Earth.

After having sent a 3D printer to the International Space Station and printed its first object, a file for a functional ratchet wrench was emailed to a laptop and printed, marking the first time an object designed on Earth was digitally transmitted into space and manufactured.

Though the news of the first 3D printed wrench in space was big in the media, the behind-the-scenes story wherein an engineer at Made in Space, a startup born at Singularity University Labs, rapidly designed the tool and quickly sought approval from NASA has not been told.

In this clip, Jason Dunn, who is the company's cofounder and Chief Technology Officer, shares the details behind what is soon to become commonplace: digital transmission of designs for offworld manufacturing.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

Want your own version of the wrench and have access to a 3D printer? NASA has made the file available for download.

If you want to learn more about Made in Space, check out this clip from a Startup Showcase event at Singularity University's Executive Program in 2013 to see the company's plans for the future.

[vimeo 131776837 w=750 h=422]

[photo credits: NASA, Made in Space]

David started writing for Singularity Hub in 2011 and served as editor-in-chief of the site from 2014 to 2017 and SU vice president of faculty, content, and curriculum from 2017 to 2019. His interests cover digital education, publishing, and media, but he'll always be a chemist at heart.

Related Articles

Elon Musk Says SpaceX Is Pivoting From Mars to the Moon

What If We’re All Martians? The Intriguing Idea That Life on Earth Began on the Red Planet

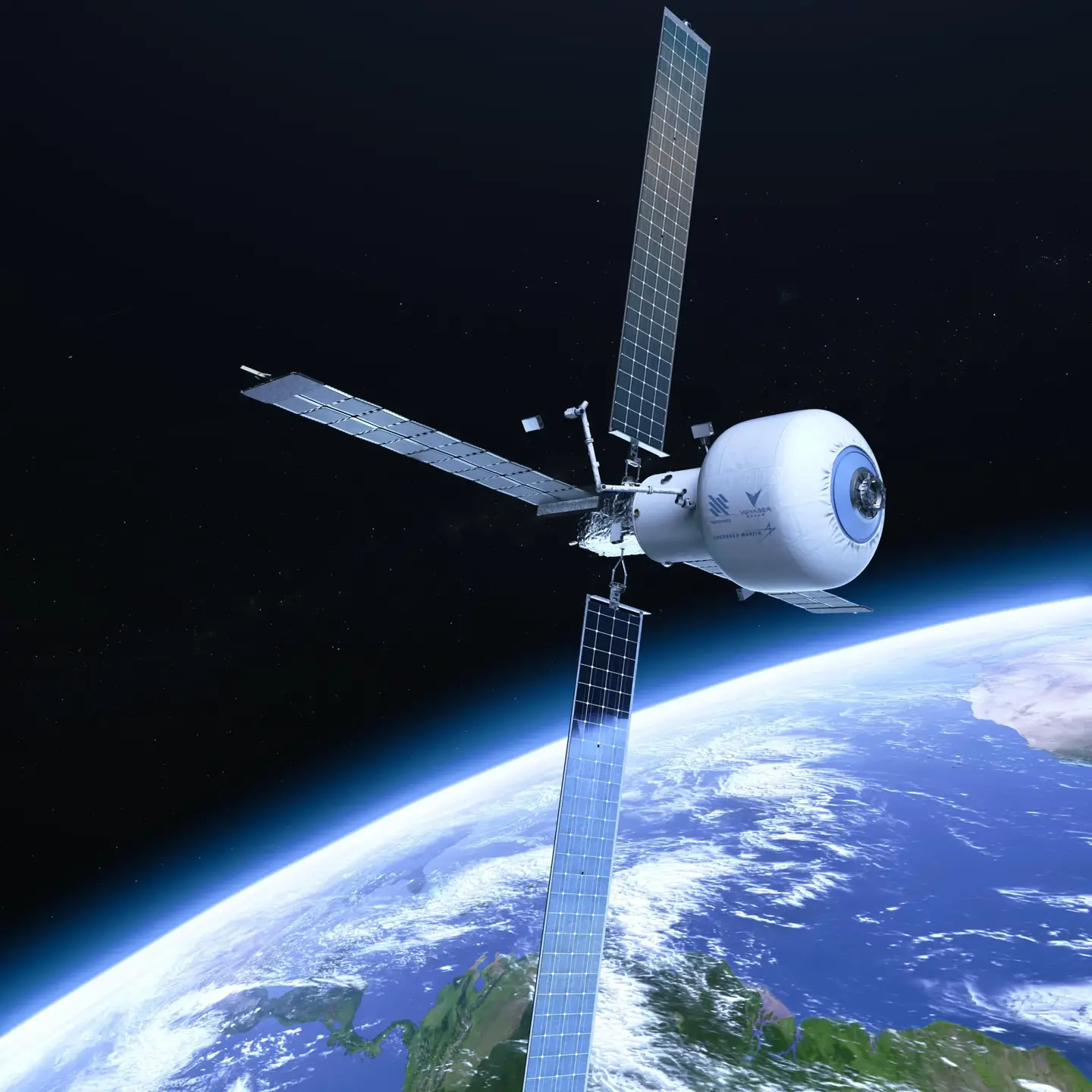

The Era of Private Space Stations Launches in 2026

What we’re reading