Amazon Robots Take Over Warehouses to Get That Thing You Ordered Even Faster

Share

It's no secret Amazon has been neck-deep in robotics for years. It began with the acquisition of robotics startup Kiva in 2012. Since then, Amazon's automation efforts have expanded to include a menagerie of over 750,000 warehouse robots for fetching, picking, and sorting.

Now the company is stringing these robots together into a kind of assembly line for the billions of packages it ships every year. According to Amazon, it launched a new system, called Sequoia, in a Houston warehouse this week.

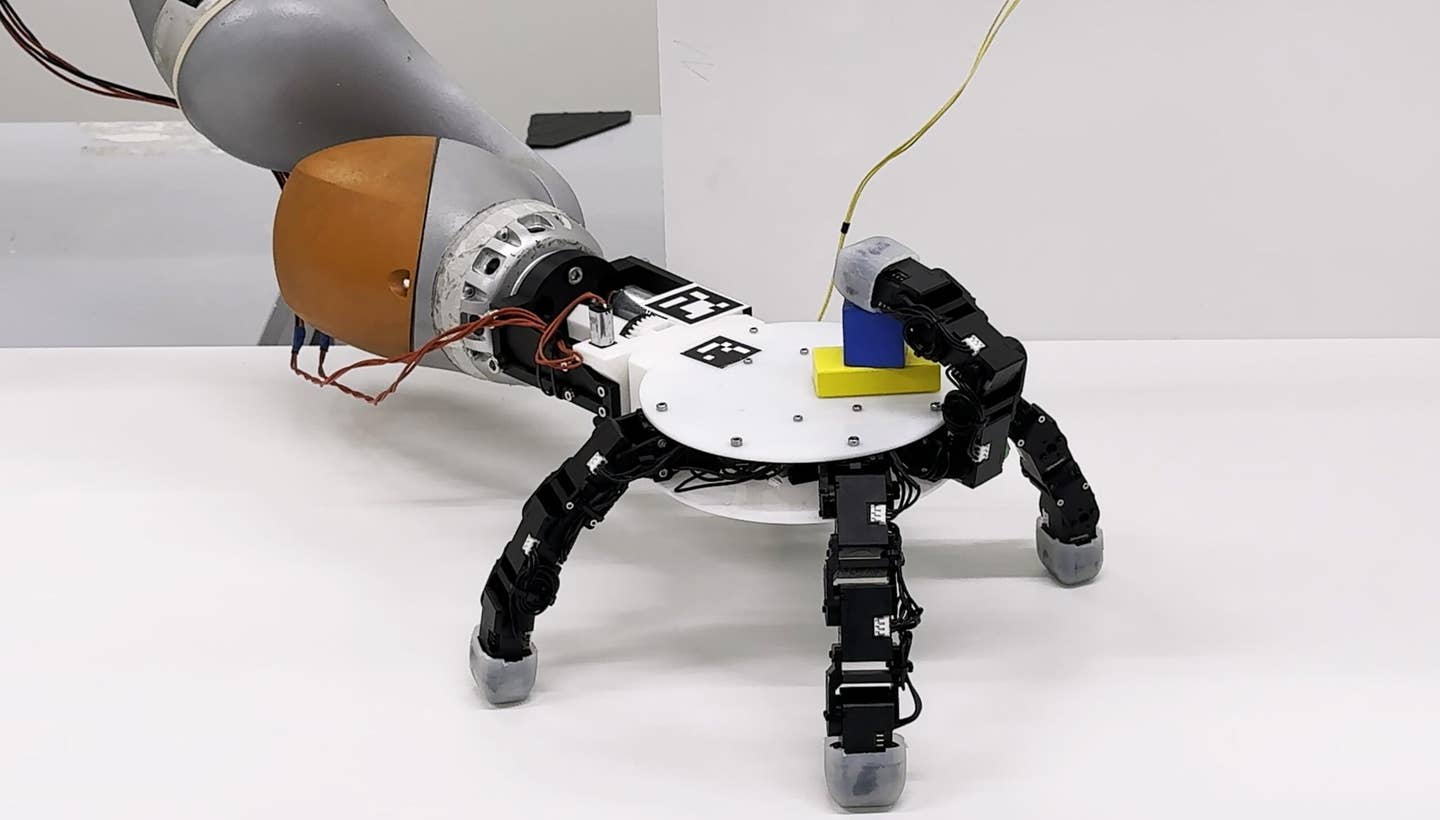

In the new process, robots pull totes from shelves and bring them over to a robotic arm equipped with computer vision and machine learning. The arm sorts the totes and sends them off to a worker for picking and packing. Another robotic arm then consolidates the remaining items for storage.

According to Amazon, Sequoia shaves 25 percent off the time it takes to fulfill orders and accelerates item identification and storage by 75 percent. The company aims to expand the system to many more of its warehouses in the coming years.

To be clear, the robots themselves aren't necessarily new. Kiva's wheeled robots started fetching towers of totes years ago, and in 2022, Amazon unveiled several new robots, including updated Kiva-style movers (Proteus) and clever robotic arms (Sparrow). What's new is the way in which these robots are being strung together into a comprehensive system that's ready to take center stage in daily operations.

"The key thing Amazon is trying to do is integrate," Rueben Scriven, research manager at market research firm Interact Analysis, told the Wall Street Journal. "They have the different pieces, and now it’s about, ‘How do we bring them together in a harmonious system?'"

Whereas blue-sky projects into sci-fi-like general-purpose robots—including the likes of Tesla, Sanctuary, and Figure (who this week unveiled a much-improved prototype)—are being pursued to fulfill nebulous future applications, Amazon's robotics efforts are rooted in hard-nosed economics. They make financial sense for the company, and the company has ample cash to invest in their development. If the earliest wave of robotics automation hit manufacturing, Amazon's warehouse work shows a new wave is well underway. Amazon competitor, Walmart, is likewise rapidly automating its warehouses.

In contrast to manufacturing, in which robots perform highly repetitive, precisely dictated actions, warehouse automation is a harder problem. Working on a warehouse floor means dodging humans and other machines and navigating a more open environment. Identifying products of all shapes and sizes and picking the exact thing a customer ordered requires the ability to see and "understand" what is being seen.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

Most of this work was out of range for robots until recently. But Amazon has been chipping away at the problem, and isn't likely to end those efforts.

The company will also begin testing the humanoid Digit robot in warehouses soon. Digit's maker, Agility Robotics, in whom Amazon has invested, announced this month it plans to open a new plant later in the year to manufacture hundreds and eventually thousands of its robots. Beyond the warehouse, Amazon is interested in self-driving vehicles, drone delivery, and would likely not be against Digit-like robots dropping packages on your doorstep.

Despite continued worries about robots taking human jobs and increasing injuries as the pace of the work accelerates, the company claims automation benefits customers and employees alike. It says its human workforce has grown alongside automation, and the vision remains one of robots and humans working together, not the former replacing the latter. Sequoia should improve safety overall, according to the company. Workers won't have to reach as high for heavy totes as they have in the past, for instance, reducing injuries. It's still an unsettled debate, of course, and it will take time to see how things shake out.

Still, with double-digit gains in speed and efficiency, Amazon isn't likely to ease back on automation anytime soon. The next time you order a last-minute gift and find it can be delivered same-day, you can thank Amazon's tireless human and robot workers for the favor.

Image Credit: Amazon

Jason is editorial director at SingularityHub. He researched and wrote about finance and economics before moving on to science and technology. He's curious about pretty much everything, but especially loves learning about and sharing big ideas and advances in artificial intelligence, computing, robotics, biotech, neuroscience, and space.

Related Articles

This Robotic Hand Detaches and Skitters About Like Thing From ‘The Addams Family’

Waymo Closes in on Uber and Lyft Prices, as More Riders Say They Trust Robotaxis

Sci-Fi Cloaking Technology Takes a Step Closer to Reality With Synthetic Skin Like an Octopus

What we’re reading