Ultrasonic 3D Printer Could One Day Repair Organs in the Body Without Surgery

Share

A plump piece of farm-fresh chicken leg rested on a pristine surface at Harvard Medical School. Skin on and bone in, it was precisely sliced to barely crack the bone.

A robot arm swerved over, scanned the breakage, and carefully injected a liquid cocktail of ingredients into the crack, including some isolated from seaweed. With several pulses of ultrasound, the liquid hardened into a bone-like material and sealed the fracture.

This wasn’t an avant-garde dinner show. Rather, it was an innovative experiment to see if ultrasound can one day be used to 3D print implants directly inside our body.

Led by Dr. Yu Shrike Zhang at Brigham and Women’s Hospital and Harvard Medical School, a recent study combined the unique properties of ultrasound and 3D printing to repair damaged tissue. At the heart of the technology is a mixture of chemicals that gel in response to sonic waves—a concoction dubbed “sono-ink.”

In one test, the team 3D printed a cartoonish bone shape inside a hefty piece of isolated pork belly, the ultrasound easily penetrating layers of fatty skin and tissue. The technology also made beehive-like structures inside isolated pork livers and a heart shape in kidneys.

It may sound macabre, but the goal isn’t to 3D print emojis inside living tissue. Rather, doctors may one day use ultrasound and sono-ink to directly repair damaged organs inside the body as an alternative to invasive surgery.

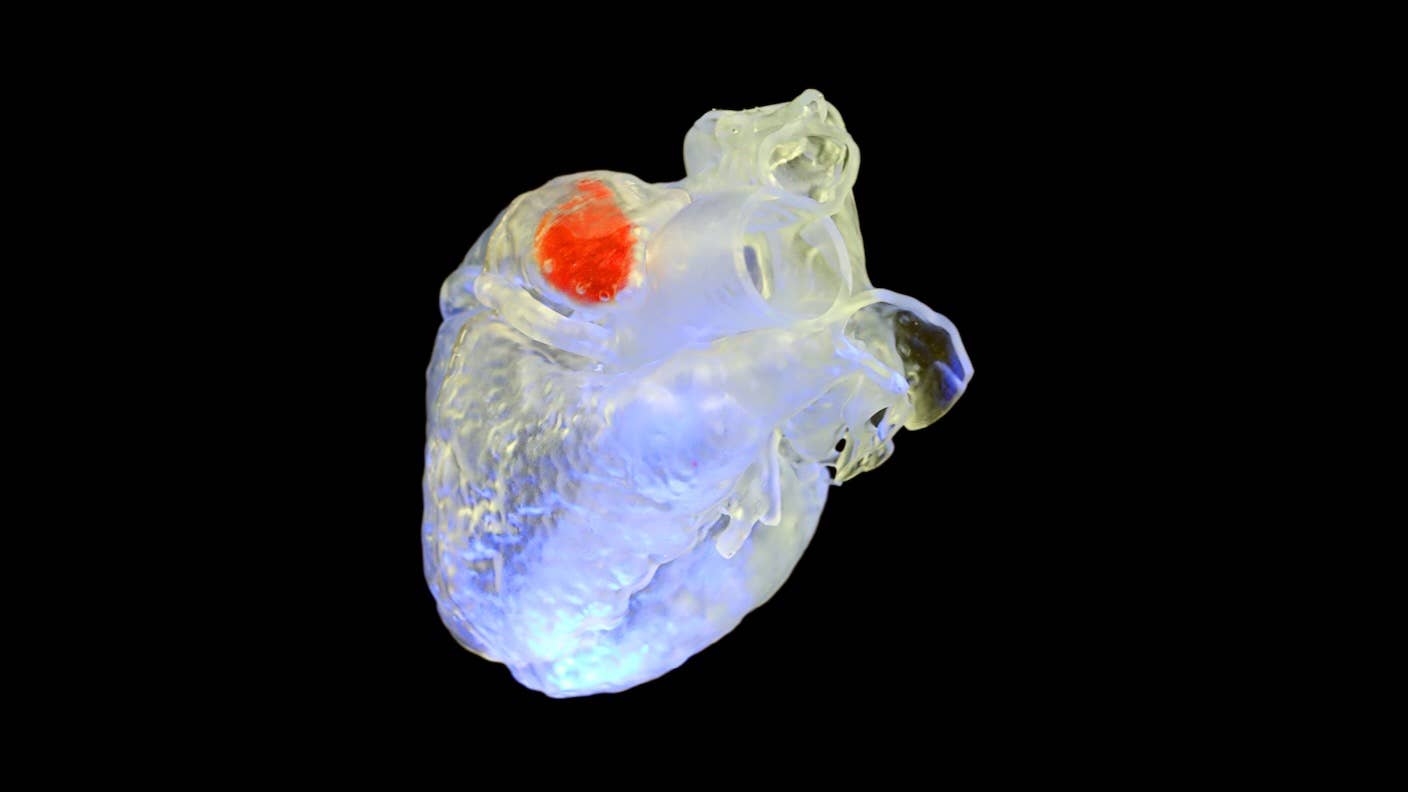

As a proof of concept, the team used sono-ink to repair a broken region of an isolated goat heart. After a few blasts of ultrasound, the resulting patch gelled and meshed seamlessly with surrounding heart tissue, essentially becoming a biocompatible, stretchable bandage.

Another test loaded the sono-ink with a chemotherapy drug and injected the concoction into a damaged liver. Within minutes, the ink released the drug into injured areas, while sparing most of the healthy surrounding cells.

The technology offers a way of converting open surgeries into less-invasive treatments, wrote Drs. Yuxing Yao and Mikhail Shapiro at the California Institute of Technology, who were not involved in the study. It could also be used to print body-machine interfaces that respond to ultrasound, make flexible electronics for heart injuries, or efficiently deliver anti-cancer drugs straight to the source after surgery to limit side effects.

“We’re still far from bringing this tool into the clinic, but these tests reaffirmed the potential of this technology,” said Zhang. “We’re very excited to see where it can go from here.”

From Light to Sound

Thanks to its versatility, 3D printing has captured bioengineers’ imagination when it comes to building artificial biological parts—for example, stents for life-threatening heart disease.

The process is usually iterative. An inkjet 3D printer—similar to an office printer—sprays out a thin layer and “cures” it with light. This solidifies the liquid ink and then, layer by layer, the printer builds an entire structure. Yet light can only illuminate the surface of many materials, making it impossible to generate a fully printed 3D structure with one blast.

The new study turned to volumetric printing, where a printer projects light into a volume of liquid resin, solidifying the resin into the object’s structure—and voilà, the object is built whole.

The process is much faster and produces objects with smoother surfaces than traditional 3D printing. But it’s limited by how far light can shine through the ink and surrounding material—for example, skin, muscle, and other tissues.

Here's where ultrasound comes in. Best known for maternal care, low levels of ultrasound easily penetrate opaque layers—such as skin or muscle—without harm. Called focused ultrasound, researchers are exploring the technology to monitor and stimulate the brain and other tissues.

It has drawbacks. Sound waves blur when traveling through liquids, which are abundant in our bodies. Used to 3D print structures, the sound waves could generate an abomination of the original design. To build an acoustic 3D printer, the first step was to redesign the ink.

A Sound Recipe

The team first experimented with ink designs that cure with ultrasound. The recipe they came up with is a soup of molecules. Some solidify when heated; others absorb sound waves.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

The sono-ink transforms into a gel in just minutes after ultrasound pulses.

The process is self-propelling, explained Yao and Shapiro. Ultrasound triggers a chemical reaction that generates heat which is absorbed into the gel and accelerates the cycle. Because the ultrasound source is controlled by a robotic arm, it’s possible to focus the sound waves to a resolution of one millimeter—a bit thicker than your average credit card.

The team tested multiple sono-ink recipes and 3D printed simple structures, like a multi-colored three-piece gear and glow-in-the-dark structures resembling blood vessels. This helped the team probe the limits of the system and explore potential uses: A fluorescent 3D-printed implant, for example, could be easier to track inside the body.

Sound Success

The team next turned to isolated organs.

In one test, they injected sono-ink into a damaged goat heart. A similar condition in humans can lead to deadly blood clots and heart attacks. The common treatment is open-heart surgery.

Here, the team infused sono-ink directly into the goat heart through blood vessels. With precisely focused ultrasound pulses the ink gelled to protect the damaged region—without harming neighboring parts—and connected with the heart’s own tissues.

In another test, they injected the ink into a chicken leg bone fracture and reconstructed the bone “with seamless bonding to the native parts,” the authors wrote.

In a third test, they mixed doxorubicin, a chemotherapy drug often used in breast cancer, into the sono-ink and injected it into damaged parts of a pork liver. With blasts of ultrasound, the ink settled into the damaged regions and gradually released the drug into the liver over the next week. The team thinks this method could help improve cancer treatment after the surgical removal of tumors, they explained.

The system is just a start. Sono-ink hasn’t yet been tested inside a living body, and it could trigger toxic effects. And while ultrasound is generally safe, the stimulation can increase sound-wave pressure and heat tissues up to a very toasty 158 degrees Fahrenheit. To Yao and Shapiro, these challenges can guide the technology.

The ability to quickly print soft 3D materials opens the door to new body-machine interfaces. Organ patches with embedded electronics could support long-term care for people with chronic heart disease. Ultrasound could also spur tissue regeneration in deeper parts of the body without invasive surgery.

Biomedical applications aside, sono-ink could even make a splash in our everyday world. 3D-printed shoes, for example, have already entered the market. It’s possible “the running shoes of the future could be printed with the same acoustic method that repairs bones,” wrote Yao and Shapiro.

Image Credit: Alex Sanchez, Duke University; Junjie Yao, Duke University; Y. Shrike Zhang, Harvard Medical School

Dr. Shelly Xuelai Fan is a neuroscientist-turned-science-writer. She's fascinated with research about the brain, AI, longevity, biotech, and especially their intersection. As a digital nomad, she enjoys exploring new cultures, local foods, and the great outdoors.

Related Articles

Souped-Up CRISPR Gene Editor Replicates and Spreads Like a Virus

Your Genes Determine How Long You’ll Live Far More Than Previously Thought

Google DeepMind AI Decodes the Genome a Million ‘Letters’ at a Time

What we’re reading