In the world of robotics, someone is always out to build a better Transformer [r]. There’s just something about robots that can change shape that makes every developer get gushy inside. You can imagine that at some point while watching the cartoon in the 80s, the robotics industry took a collective sigh and said, “I want to build one of those.” So they have. My goodness, the number of transforming robots has gotten so crazy we here at Singularity Hub thought we’d take you on a short video tour and discuss what makes these real-life changing robots so desirable. Stay tuned for way too many videos after the break.

First though, we should clarify lest you think we’re going to show movie clips of cars changing into androids. No, we’re talking real life robots here, and they’re modular. Modular robotics focuses on building a single section of a robot (a module) that can combine with other modules to form different kinds of macrobots. They can transform into walking machines, snakes, and wheels to help them move around, accomplish tasks, and beg for money. NASA, military developers, search and rescue teams, and mining companies have all been throwing money into modular robot research. The goal: find the best way to create adaptive and robust robots that can built by mass producing a simple module.

The typical module of a modular robot is a cube (or two cubes) that can flex in one or two directions. Using magnets, gripping pincers, or other mechanism, these cubes will interlock forming larger sections. Each module in the section communicates with others using radio frequencies, infrared, or surface electrical signals. With a common set of programming parameters, these modules work together to make the larger section change shape, move, or manipulate an object. For instance, Palo Alto Research Center has developed Polybot, a modular robot that can be adapted to many different tasks. It can even ride a tricycle.

Welcome to the Modular Circus

Of course one of the first widely successful modular robots came from the Japanese. AIST and Tokyo Tech built the MTRAN Mark I which first traveled the robotic show circuit in 1999, though the concept had been building since 1988. The MTRAN III, which debuted in 2005, got major industry hype. It was able to traverse a wide variety of terrain, reshaping itself for each. Proximity and gravity sensors helped it navigate. The following video is way too long, so fast forward through and watch the highlights.

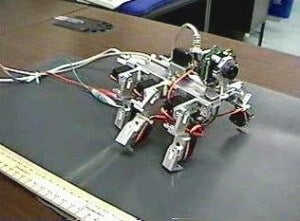

In the U.S, the Polymorphic Robotics Institute at the University of Southern California built two versions of modular robots. The first, CONRO, was developed in 1998 and was supposed to be aid in military reconnaissance. Its creators pioneered a concept known as “software hormones” – a way to pass signals from module to module so that the entire macrobot knew and agreed on what shape it should have. This allowed CONRO modules to function as a very cohesive unit.

The successor to CONRO was Superbot, which, although more than 5 years old, is still getting major press and You Tube coverage. Superbot built upon CONRO’s software hormones and is able to get its modules to find each other and self assemble. Professor Wei-Min Shen explains it best in this BBC segment from January 2008:

Of course, with the Superbot came a very disturbing trend: euro-techno music and robot montages. Turn down the volume and browse through this video to see the Superbot get put through its paces. How cool is it to see a robot that can form into a wheel and roll?

Superbot’s ability to form itself isn’t unique. Self-assembly is a key ingredient in CK Bot from the University of Pennsylvania’s GRASP lab. Because each module is able to locate and unify with other modules, the macrobot could conceivably be formed by launching a single module into a location one at a time. With such a technique, modular bots are likely to form a big part of future space endeavors. In such harsh and distant environments you would need a robot that could not only assemble itself, but repair itself as well. Luckily, CK Bot has that covered. Watch the opening of the following video from New Scientist, but be prepared to skip forward to its conclusion:

Cube-based modules and transformations lend themselves to a variety of possible locomotions. No where is this more apparent than in the recent ModSnake from Carnegie Mellon University’s Biorobotics Lab. The ModSnake is exactly what its name implies: a modular robot that forms into a snake. While the modules don’t demonstrate the same complex forming and transforming as MTRAN or Superbot, ModSnake can move like no other. Enjoy another round of techno as you watch it slither in the video below:

Looking Forward to Cybertron

Looking at ModSnake helps to put modular robotics in a larger context. The basic design choice of building a robot from modules allows robotic engineers to combine transformers, biorobotics and swarm robotics in one unit. Here we see the true advantage of modular robots: they can change to fit the task. The same basic robot, the module, becomes capable of accomplishing almost anything when working in a collective. With “software hormones” and advances in AI, the modular robots of the future will be able to macro and micro manage a situation, solving the big problems and little problems simultaneously.

Given the right software and small enough modules, these robots could even take on human tasks. As nanotechnology allows us to build smaller modules, we could see the humanoid robots of the future form from complex amalgams of smaller robots. In the worst case this would produce sentient “gray goo” out to destroy humanity. More likely however will be adaptive robotics that can go places humans are unable: inside the body for surgery, in deep space for exploration or terra-forming, in waste processing, or cleaning polluted environments.

The missing ingredient necessary to accomplish any of these tasks, however, is reproduction. All of our video examples can change their form, but none can build a new module from scratch. That’s the next step and one we’re anxiously awaiting. The problem solving skills of modular robots will shoot forth astronomically once they can recreate themselves. At that point, we may no longer be looking at movies and thinking “I really wish I had a transforming robot.” Instead, we’ll look at our creations and think, “Hey, this would make a great movie.”

Didn’t get enough modular robot videos? Follow these links to see some of the many videos we didn’t have time to mention: