On the Internet of Things IBM Tracks Your Pork From Farm to Fork. Starting with China

Share

IBM has set out to prove it can revolutionize the food industry with data, starting with China. Six industrial slaughterhouses and 100 markets in Shandong Province are part of a large scale test in tracking pork from farm to customer. Pigs are marked with ear tags containing unique barcodes, those same barcodes appear on the bins that carry their meat during processing, and on the packages for the pork placed in stores. In the near term, IBM hopes that knowing the history of every piece of meat will enable fast and super accurate recalls in case of contamination. Eventually, this kind of comprehensive tracking could help farmers keep pigs healthier, improve the quality of meat after it is cut, and even place a picture on the store package of the exact pig made into that pork product. Knowledge is power in this new take on the supply chain.

Food contamination leads to deaths and illness all over the world, even in more industrialized nations. In lost food alone, such outbreaks cost companies hundreds of millions of dollars a year. A particularly aggressive case of Porcine Reproductive and Respiratory Syndrome Virus (PRRSV aka Blue-Ear Disease) struck China in 2007 and may have befouled 25 million of the nation's ~660 million pigs. A lack of comprehensive tracking and pig-health monitoring meant that tons of healthy meat had to be wasted to protect consumers, even while recalls and warnings devastated consumer morale. As IBM points out in their Smarter Planet campaign, supply chain tracking could drastically reduce the impact of food contamination in meat, produce, or any product.

The trial in Shangdong Province is relatively small now, and won't be fully deployed until 2013. However, at that point, the project will be ready to expand and it's hoped that early success will encourage IBM and its partner, the Lushang Group, to bring this level of food tracking to China's entire pork industry. Considering that China is the world's leading pork producer (larger than dozens of the trailing nations combined), the possible size of this project is immense and globally impacting.

Greater gains, however, may be had not by the expansion of the number of pigs tracked, but in the data gathered. Most of the focus is simply on knowing with which pig a package of pork originated, and using that trail to quickly solve contamination issues. Yet the infrastructure put in place, centered on cloud based data storage, is ready to become so much more. Farms could upload data from pig health monitors (body temp, weight, sleep cycles, etc). On the production side of the equation Lushang and IBM are installing cameras, temperature gauges, and humidity sensors to record the processing and storage conditions of every piece of pork. They've also enabled retailers to track sales. Eventually data could also be used to help sell their pork (this meat got here in just 24 hours!), or even correlate consumer habits with trends further back in the production line. All that data is stored and associated with the same barcode, giving every piece of bacon or sausage a personal history enhanced by data and GPS location. Imagine a world where you could use your smart phone to read a code on a meat package and instantly see every detail about the pig it came from, the route it took to get to you, and all possible health risks.

That's part of the dream behind IBM's Food Technology portion of their Smarter Planet initiative. From pigs to tomatoes, comprehensive tracking could help guarantee freshness, improve production standards, and even automatically route food shipments based on consumer trends. There are some serious dollars to be saved by upgrading to these kind of supply chain logistics.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

As the above video mentions, the trial with pork on Shangdong Province isn't the only such project currently underway. Similar efforts are being made with other food products in Vietnam, Thailand, Norway and Canada. IBM even has an unnamed partner in the US working with fresh produce.

Cheap sensors, cloud computing, and nigh-ubiquitous GPS tracking are all coming together to enable the next generation of data gathering. IBM is already leveraging this evolved form of data collection for prescription medicine, various food products around the world, and now pork in China. Such supply chain logistics are just one of the earliest innovations from the Internet of Things – the growing network of smart objects that produce and interact with digital information. With the millions (or billions) of dollars these programs will save, IBM and its partners should continue to march towards a future where every consumer good comes accompanied by a digital history. Learning more about what we buy, and especially what we eat, is one of the closest and most empowering promises in our future. Get ready to know your food.

[video credit: IBM Smarter Planet]

[source: IBM Smarter Planet, IBM Press Release]

Related Articles

How Scientists Are Growing Computers From Human Brain Cells—and Why They Want to Keep Doing It

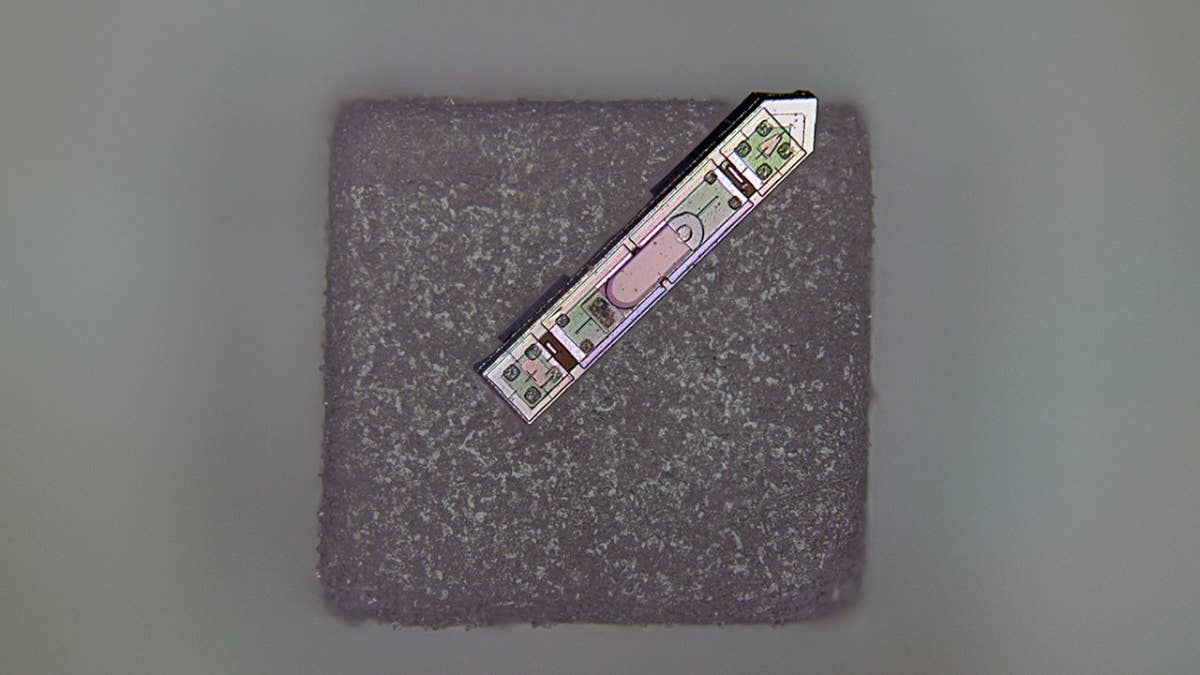

These Brain Implants Are Smaller Than Cells and Can Be Injected Into Veins

This Wireless Brain Implant Is Smaller Than a Grain of Salt

What we’re reading