3D Printer Cranks Out Exquisite Structures Smaller Than Dust Mites And Sets A New World Record

Share

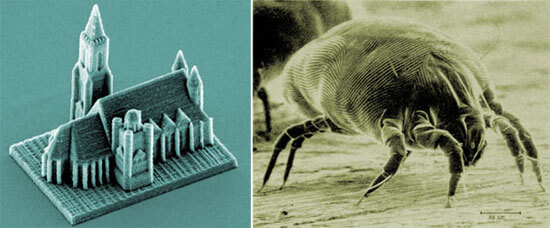

Researchers from the Vienna University of Technology have refined a 3D printing technique to make incredibly small structures at record-breaking speeds. The technique, called two-photon lithography, allows the sculpting of intricate objects with micron precision at a rate of 5 meters per second, which is 50,000 times faster than typical processing speeds. The team demonstrated the fabrication from CAD files of St. Stephen's cathedral, the London Tower Bridge, and even a race car that measures about 300 micrometers long, just under the size of a dust mite barely visible to the human eye. The momentum for developing 3D printing techniques continues to build, so the pressure is on to produce complex structures at lightning fast speeds that can be commercialized for electronics, biomedicine and nanotechnology.

Here's the fabricated intricate and detailed cathedral with resolutions at 100 nanometers next to a dust mite:

This new two-photon lithography is a prime example of what multidisciplinary research can achieve.

Researchers Jan Torgersen and Peter Gruber were able to develop this high resolution methodology thanks to the input from experts of various fields. While some scientific fields can tolerate scientists conducting their research in relative isolation, it's frequently not the case in material science, which is an amalgam of engineering, physics, chemistry, and in certain applications, biology. So, the team relied on chemists to develop the photoactive molecules used in the liquid resin. This chemical require two kinds of light for the polymerization or hardening of the resin to occur. The polymer forms at the focal point of the two light beams where the light is intense enough to initiate the chemical reaction, allowing for high degrees of control. This avoids the need to create structures as two-dimensional sheets formed one at a time, saving time and providing more sophisticated structures to be generated. The light system delivers femtosecond pulses synchronized with continuously moving mirrors that are far from the sample, such that a slight shift in the mirror angle produces a large sweep within the resin itself.

The high speeds of fabrication are demonstrated in the production of the F1 race car, which consists of 100 layers each containing 200 lines and was produced in 4 minutes, as seen in the following video:

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

While this lithography technique is a success, the team plans to continue to improve it with the goals of high throughput and reliable fabrication while minimizing the cost of the system for industrial applications. Additionally, they are investigating bio-compatible resins, potentially opening the door to super fast tissue generation, something that other researchers are turning to 3D printing to manufacture as well.

Richard Feynman, the infamous CalTech physicist, once said about the future miniaturization of computers that "There's plenty of room at the bottom." In other words, if the technology could be developed to make structures with nanoscale precision, the possibilities would be endless. Because of the gap difference between human scale and the absolute limit that objects can be built at, which is arguably the near-atomic scale, there is plenty of space to build things that perform functions at that size but are amplified to the human level. As lithography techniques become increasingly sophisticated and fast, it's clear that there is a race to the bottom, as technology continues to push to make things smaller.

As we herald these breakthroughs, it is also important to peer into the future of these techniques to see how they will shape technology (pun intended). For instance, the resolution of tablets has been increasing, as in the iPad 3, thanks to improved lithography techniques, which also help to make chips even smaller. Even more sophisticated lithography may someday produce materials that are invisible. But the work from the Viennese team is a reminder of the very real possibility of intricately designed electronics or other structures that could someday exist right under our noses without us even being aware, the kind of scale anonymity that dust mites currently enjoy (apologies to those with hypochondriac tendencies).

Thanks to a Singularity Hub member for pointing out the awesome work being done in Vienna.

[Media: TUWien, Wikipedia, YouTube]

[Sources: Popular Mechanics, TheEngineer, TUWien]

David started writing for Singularity Hub in 2011 and served as editor-in-chief of the site from 2014 to 2017 and SU vice president of faculty, content, and curriculum from 2017 to 2019. His interests cover digital education, publishing, and media, but he'll always be a chemist at heart.

Related Articles

This Portable Wind Turbine Is the Size of a Water Bottle and Charges Devices in Under an Hour

Mojo Vision’s New Contact Lens Brings Seamless Augmented Reality a Step Closer

The Weird, the Wacky, the Just Plain Cool: Best of CES 2020

What we’re reading