New At The Dentist: 3D Printing “Dental Crowns While You Wait”

Share

The trip to the dentist just got a little less painful, at least in terms of time spent there. A new system is being used by a handful of dentists to scan patients’ teeth and create crowns for them while they wait. A process that normally takes two weeks, now only takes an hour.

Instead of making a mold and sending it to a lab for scanning, dentists are now using a small camera to scan the misshapen teeth directly. The digitized scan is then sent to an on-site milling machine that carves the crown from a block of porcelain – in about an hour. After about 15 minutes of preparation the crown is ready to be implanted. No need to walk around for two weeks, waiting, with a temporary filling. Read a few magazine articles while the crown's prepared, and soon you're on your way.

The system is provided by Sirona. The company is one of the first to use computer-aided design (CAD) and manufacturing (CAM), as evidenced by their 95 percent of marketshare. They offer their system, called Cerec, to dentists for about $100,000. The in-house systems aren’t widespread just yet – only about 1 in 10 dentists use CAD/CAM to make crowns on-site. But as more patients become accustomed to the single visit convenience of crowns-made-while-you-wait, there could be more pressure for dentists to adopt the tools of their competitors.

Dentists are now taking out the mold and the middleman.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

Normally getting a crown, a restorative ceramic cap that is cemented atop a damaged tooth, begins with the dentist drilling into the damaged tooth for a good fit. After drilling, a mold is made of the tooth, and the mold is sent to an outside lab where its 3D structure is scanned and digitized. That digitized image is then sent back to the dentist who makes modifications as needed, and once again it’s back to the lab where the crown is finally made. The entire process normally takes about two weeks. In the meantime, the dentist implants a temporary filling to protect the drilled tooth.

That widespread use could be slowed, however, from several limitations. Because the scanners can’t scan beneath the gumline, any tooth damage occurring below the gumline would necessitate a mold. In addition, the carving process is not sufficiently agile to faithfully reproduce the intricate variations of a real tooth. For this reason, replacements for the very visible front teeth will remain the job of mold-based machines.

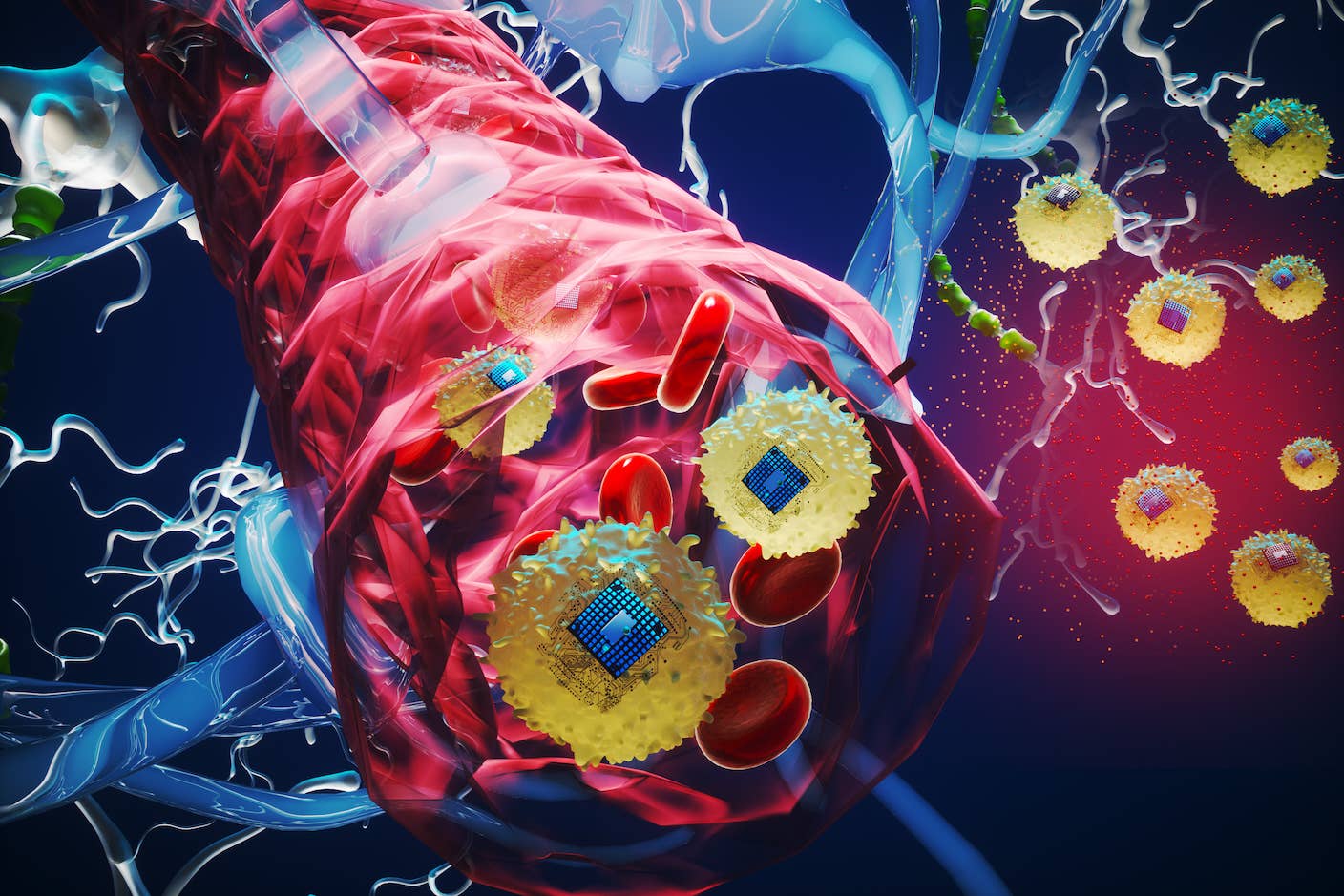

With the advent of more sophisticated scanning technologies, CAD and CAM will continue to move into the medical space. Last year an orthopedic surgeon combined CT scans and 3D printing to come up with a way to produce 3D models at about a tenth the cost of conventional methods. Bespoke Prosthetics scans the intact limbs of amputees to help create prosthetics that are not only beautiful but match the amputee’s proportions. And it’s possible that tomorrow’s labs will be able to produce more than the hard replicas of bones and teeth. Whole organs, printed cell layer by cell layer, could be produced on the spot, tailored to a patient’s specific needs. Computer-aided design and 3D printing will continue to transform design and production of manufactured goods, and increasing number of which will become parts of our own bodies.

Peter Murray was born in Boston in 1973. He earned a PhD in neuroscience at the University of Maryland, Baltimore studying gene expression in the neocortex. Following his dissertation work he spent three years as a post-doctoral fellow at the same university studying brain mechanisms of pain and motor control. He completed a collection of short stories in 2010 and has been writing for Singularity Hub since March 2011.

Related Articles

This Light-Powered AI Chip Is 100x Faster Than a Top Nvidia GPU

How Scientists Are Growing Computers From Human Brain Cells—and Why They Want to Keep Doing It

These Brain Implants Are Smaller Than Cells and Can Be Injected Into Veins

What we’re reading