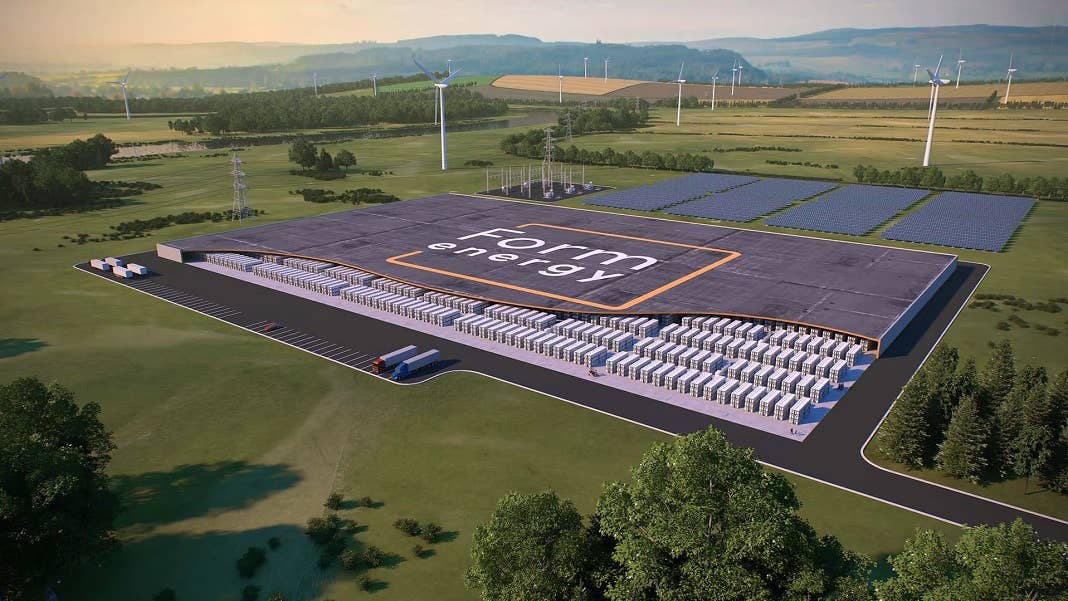

Form Energy’s New Factory Will Churn Out Iron-Air Batteries for Grid-Scale Storage

Share

This past May the Biden administration allocated $3.16 billion in funding to start securing a battery supply chain for the US. Much of the focus has been on lithium-ion batteries for electric vehicles, but soon a different kind of battery will join the fray. The Gates-backed battery startup Form Energy recently announced plans to build a $760 million factory for its iron-air batteries.

These batteries are made for storing electricity produced by renewables like solar and wind, and a few key features differentiate them from lithium-ion.

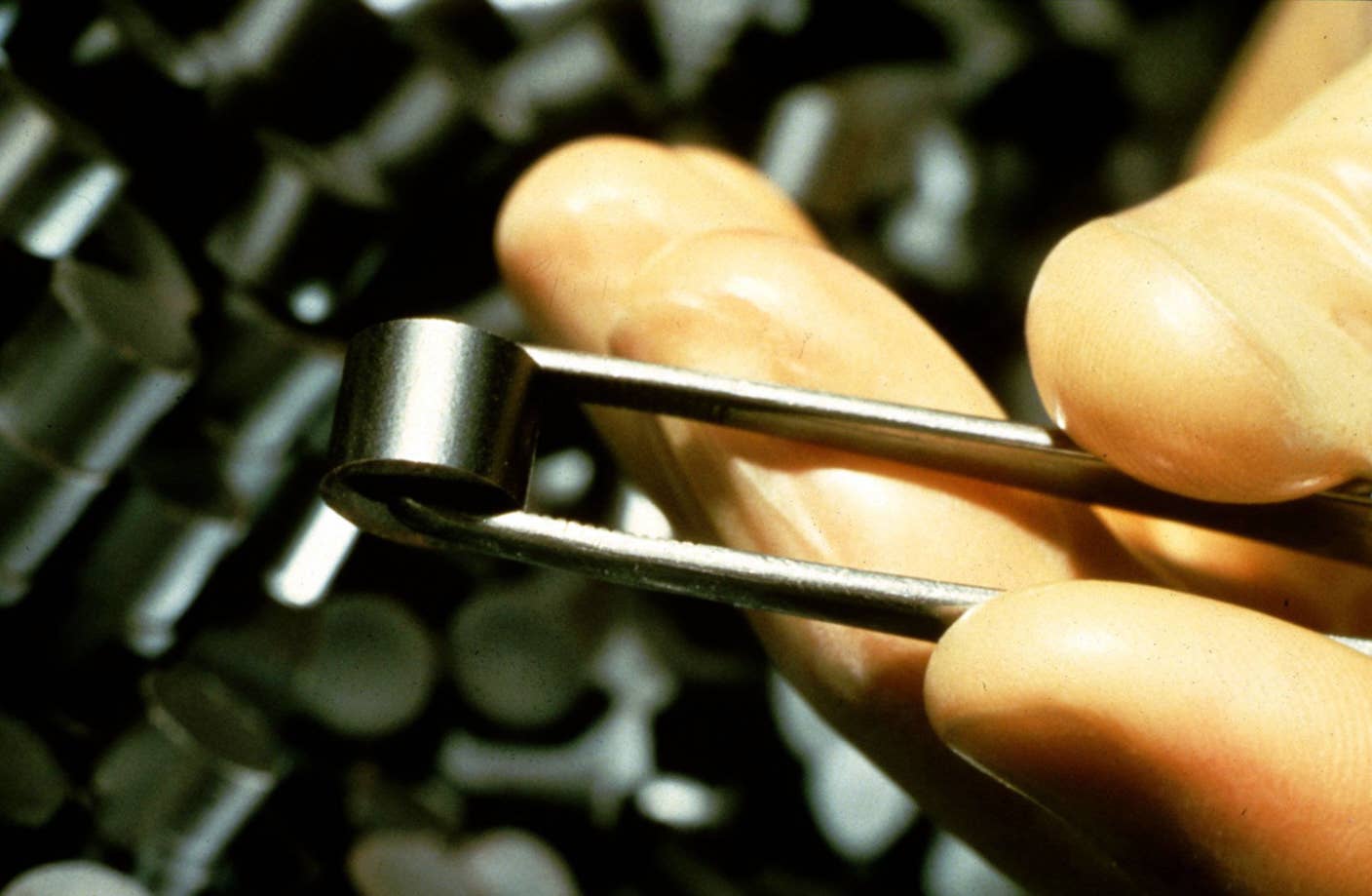

Each battery is as big as a washing machine and holds 50 iron-air cells, which are flat and about a square meter in size. The cells are surrounded with a water-based electrolyte similar to what’s used in AA batteries. To discharge, the battery breathes in oxygen from the air, converting the iron to iron oxide—commonly known as rust—and producing electricity in the process. Applying a current converts the rust back into iron, expels the oxygen, and charges the battery.

Iron-air batteries have two big advantages over lithium-ion. The first is cost. Iron is cheaper and far easier to procure than minerals like nickel, cobalt, or lithium. Form Energy says they can make their batteries at a cost of $20 per kilowatt hour, less than half the cost of lithium-ion batteries.

The second advantage is duration: iron-air batteries can store power for 100 to 150 hours. This would come in particularly handy for storing energy generated by renewables like wind or solar, whose intermittency prevents them from being reliable baseload power sources.

The flip side of slow discharging, though, is slow charging; it takes iron-air batteries longer to charge than their lithium-ion counterparts. Form plans to create “powerblocks” made up of thousands of batteries, which will likely be used alongside conventional batteries; iron-air would power longer load demands and lithium would be there for demand spikes.

A final advantage of Form’s batteries is that they’re recyclable. The metals used to make them can be extracted at the end of a battery’s life and used elsewhere (this is precisely what a battery recycling plant under construction in South Carolina will do, except with conventional batteries).

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

Late last month, the company announced plans to partner with the state of West Virginia to build its first manufacturing plant in a former steel-producing town called Weirton. The facility will sit on 55 acres and employ around 750 people. Construction is expected to start this year, and the first batteries will come off the production line in 2024.

Form received $450 million in Series E funding last October, bringing its total funding to over $800 million. The company has a contract in place to install a 150-megawatt-hour battery in Minnesota and is looking to do a similar pilot in Georgia.

Whether iron-air batteries can truly make a dent in the renewables storage dilemma remains to be seen, but signs point to Form Energy being set up for success.

Image Credit: Form Energy

Vanessa has been writing about science and technology for eight years and was senior editor at SingularityHub. She's interested in biotechnology and genetic engineering, the nitty-gritty of the renewable energy transition, the roles technology and science play in geopolitics and international development, and countless other topics.

Related Articles

US Solar Surged 35% in 2025, Overtaking Hydro for the First Time

Meta Will Buy Startup’s Nuclear Fuel in Unusual Deal to Power AI Data Centers

Your ChatGPT Habit Could Depend on Nuclear Power

What we’re reading