Considering the pace of technological growth in recent decades, the convergence of humans and machines seems a foregone conclusion. Yet, unlike most machines, the body is far too flexible and squishy for modern advanced materials. So it falls on researchers to develop new stretchable technologies that are easily manufactured and relatively inexpensive.

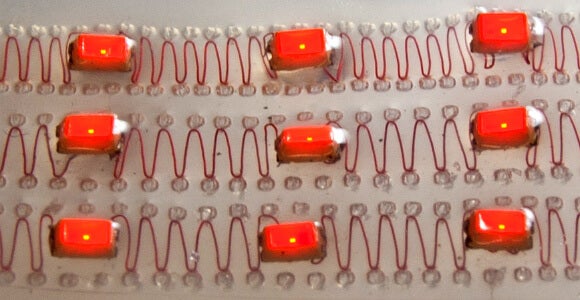

Recently, a biomedical engineering team at Purdue University developed a methodology to generate zigzag patterns out of conventional wire that can extend up to five times in length. The wires can be utilized as conductive interconnects between sensors, allowing for flexible networks or meshes to be embedded or wrapped around 3D objects.

“This compares to only a few percent for an ordinary metal connection,” said Professor Barak Ziaie, leading the research in the press release. “The structures are also highly robust, capable of withstanding thousands of repeated stretch-and-release cycles.”

Even more intriguing, the approach utilizes a standard sewing machine to fabricate the system.

Using water-soluble thread, the technique involves stitching wire in zigzags onto standard transparencies used with overhead projectors. A commercially available elastomer called Ecoflex is poured over the sheet and allowed to solidify. The thread is dissolved with warm water, allowing the flexible polymer with the embedded wires to be separated from the transparencies.

To demonstrate how their approach could be used for medical devices, the team generated a sensor system that wraps around a urinary catheter balloon – as the balloon inflates, the sensor gauges the strain. This flexible system can measure much greater expansion than conventional approaches that employ rigid metal films that permit only small percentages of stretching before breaking.

To demonstrate how their approach could be used for medical devices, the team generated a sensor system that wraps around a urinary catheter balloon – as the balloon inflates, the sensor gauges the strain. This flexible system can measure much greater expansion than conventional approaches that employ rigid metal films that permit only small percentages of stretching before breaking.

The findings, to be published in a forthcoming paper, were reported at the Solid-State Sensors, Actuators and Microsystems Workshop.

On the cusp of an era that will likely see the proliferation of soft robotics, wearable electronics, and medical implants, the need for stretchable electronics is mounting. Wearables that can sense our environments along with our physiological response could keep us aware of the impact of air quality on our breathing rates, for example. Health monitoring smart devices may begin as watches or bands, but ultimately we’ll want to know what’s going on inside of our bodies. Furthermore, lifelike androids will require human-like skin to bridge the Uncanny Valley and that means flexible synthetic materials embedded with sensors.

“You would need a low-cost, highly stretchable electrical conductor to interconnect sensors and other components in these applications,” said Ziaie.

Complex or costly approaches to these challenges will be prohibitive to widespread adoption, so methods like this that are cheap and work with existing manufacturing are highly appealing.

Image Credits: Purdue University photo/Babak Ziaie