In September, Made In Space and NASA partnered to deliver the first 3D printer to the International Space Station (ISS). And now this week, another first. The ISS astronauts fired up the printer to produce history’s first 3D printed part in space.

Our ability to establish a permanent presence in space and venture beyond Earth orbit requires self-reliance—we have to live off the land. But as things stand, we need a rocket to deliver every new tool or replacement part. 3D printing promises to be a big part of the solution. Instead of waiting months for that screwdriver or air filter, astronauts will soon print these things on demand.

But 3D printing in a low-gravity environment is not simply a matter of hoisting an off-the-shelf machine into orbit. A 3D printer in space has to compensate for the lack of gravity pulling material through the print nozzle; it has to be specially designed to transfer heat in lieu of convection; and it has to control emission of noxious fumes.

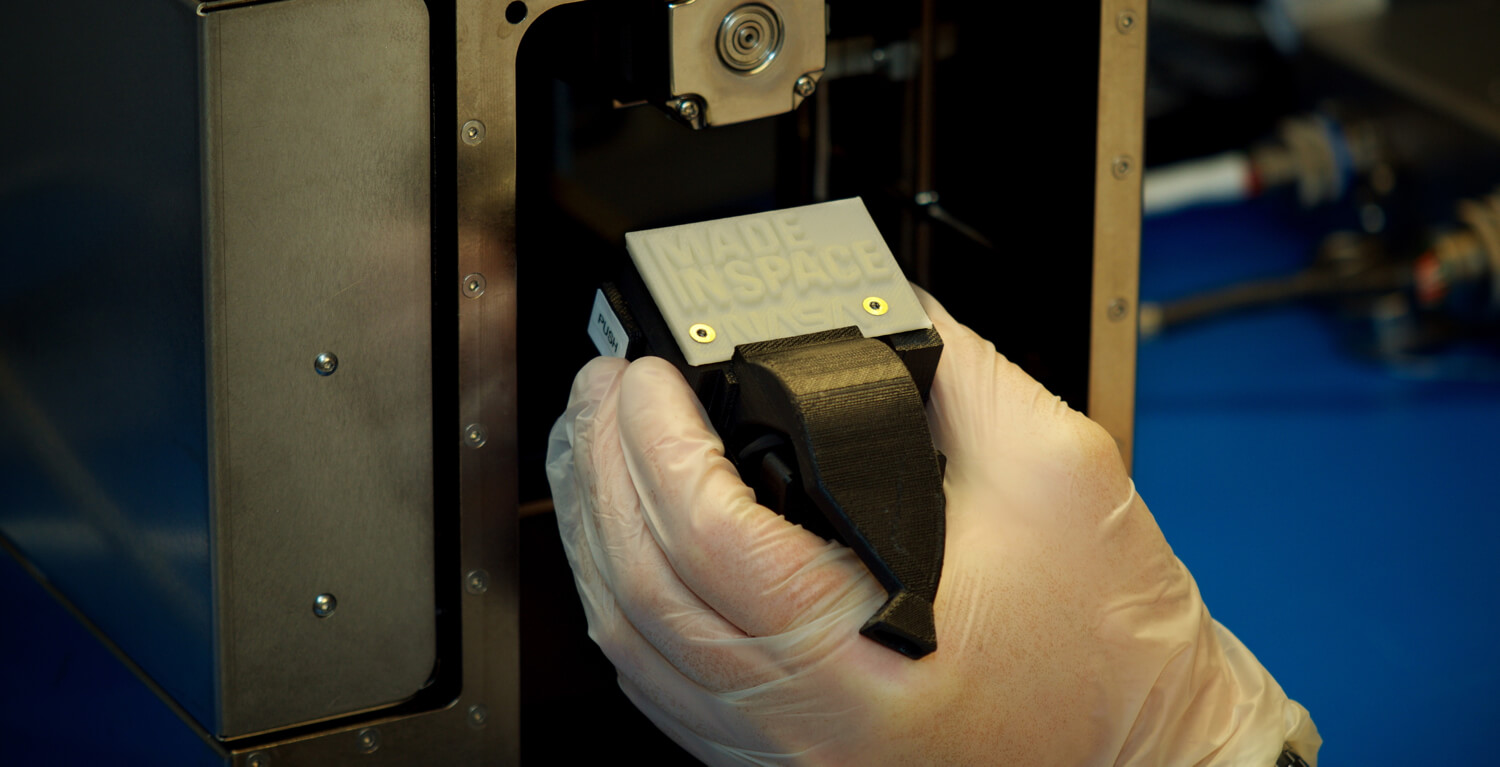

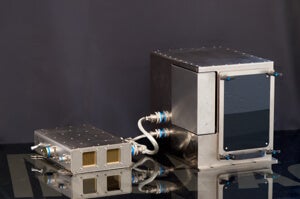

After a few years’ development and rigorous testing of their 3D space printer, the Zero-G, Made In Space (and NASA) officially have the first 3D print run in the books.

What was this famed inaugural item? A Chris Hadfield bobblehead? Sadly, no. The team printed something less entertaining on the surface, more meaningful underneath—the faceplate for the machine’s own printhead.

This is significant because it represents the beginning of a closed off-Earth manufacturing loop. Said another way, space 3D printers will be able to print replacement tools and parts—but maybe even print their own replacement parts too. It might be awhile, but eventually a 3D printer might be entirely self-replicating.

Up next, the Zero-G will print a range of test pieces, each of which will be printed in parallel on an identical printer back here on Earth. The objects printed in orbit will be returned to Earth and compared to their terrestrial counterparts to determine how various properties like tensile strength, torque, and flexibility differ.

This data will inform development of a second 3D printer, destined for the ISS in early 2015. The second printer will be made available to the ISS astronauts, of course, but also businesses and individuals wishing to print and test hardware.

The Made In Space press release stated their 3D printer allows hardware designs to be “digitally beamed” to orbit where it can be made manifest in a matter of hours. I take their casual use of the word “beamed” as more than a hint that they’re Trekkies. In light of that, let’s consider how 3D printing is half replicator, half transporter.

Of course, 3D printing has long been compared to Star Trek’s replicator. Is it able to deliver a cup of piping hot Earl Grey? No. But the comparison frames what a 3D printer does—it precisely arranges matter into specific objects on demand.

Now for the other half, the transporter: “In Star Trek’s Transporter device, normal matter is converted temporarily into energy, then beamed to a target point for restoration to its original pattern and structure. The Transporter has a range of about 16,000 miles.” Adapting this to the 3D printer now sitting on the ISS, the description would read: “In [Made In Space’s Zero-G 3D printer], normal matter is [digitized], then beamed to a target point for restoration to its original pattern and structure. The [Zero-G] has [no known limit to its] range.”

At the risk of overhyping anything here, it’s worth framing this accomplishment for what it is—Star Trek technology.

Perhaps it’s just a flight of fancy, but it is a 3D printer in orbit, after all. Nothing special.

Image Credit: Made In Space