You can print wild designs using a 3D printer—shapes you couldn’t make any other way. But 3D printing is also still in thrall to the laws of physics. To date, 3D printed structures made in metal or plastic need to support themselves as they’re built. Each layer must harden before the next one is laid down. And though we’ve expanded the materials we can print with, designs using soft materials are more difficult.

“In simple terms, a hundred-plus years that we’ve built a foundation on in traditional mechanics is largely off the table with soft matter,” according to David Hahn, chair of the University of Florida’s department of mechanical and aerospace engineering. “It really is a whole new frontier of engineering.”

“In simple terms, a hundred-plus years that we’ve built a foundation on in traditional mechanics is largely off the table with soft matter,” according to David Hahn, chair of the University of Florida’s department of mechanical and aerospace engineering. “It really is a whole new frontier of engineering.”

Using standard 3D printing you can’t, for example, print a soft jellyfish. The tentacles won’t support its weight, and printed upside-down they’d flop around—the printer can’t find a consistent spot to add the next layer. Materials collapsing also makes bioprinting soft tissues with vasculature, key for printed organs, difficult.

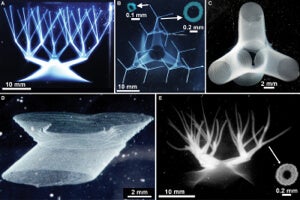

However, a recent University of Florida paper, coauthored by professors Tommy Angelini and Greg Sawyer, describes a fresh take on 3D printing soft materials using a supportive granular gel matrix that’s 99.8% water and packed with microscopic hydrogel particles.

The printer uses a hollow tip needle to precisely inject a soft printing material into the gel matrix. Guided by a digital design, it can print complex shapes that are supported by the gel, and even as the needle continuously disturbs the gel above the shape its tracing, the particles rapidly reconstitute themselves (i.e., the gel is self healing).

The team’s printed various shapes in hydrogel and silicone, including Russian nesting dolls, jellyfish, knots, and thin branching networks reminiscent of vasculature. They even printed a replica of neurosurgery professor Frank Bova’s brain. Future surgeons might practice on such replicas.

“With this process, we can take a brain scan with a tumor and make tissue that looks like that of a real patient, and that will help us better train surgeons,” Bova says.

But the team’s more revolutionary interest lies further afield. They’ve begun to print using living cells (human blood-vessel and canine kidney cells). A major challenge in 3D printing living tissue (and maybe one day entire organs) is including the elaborate network of blood vessels that keep cells stocked with nutrients. Printed vasculature tends to collapse before the 3D printed tissues are finished.

The University of Florida technique may represent a promising step in the right direction in the field, though one drawback could be that because the gel matrix is inorganic (at the moment, at least) living tissue might not survive long in it.

Just what the technique might be used for in the future is an excitingly open question, and the team will continue testing. They say the objects already printed are far softer than other man-made items, and they haven’t yet established the lower bound to just how soft they can make objects in the lab.

“We can make a cloud,” Sawyer says.

Image Credit: Shutterstock.com; University of Florida; “Writing in the granular gel medium,” Science Advances