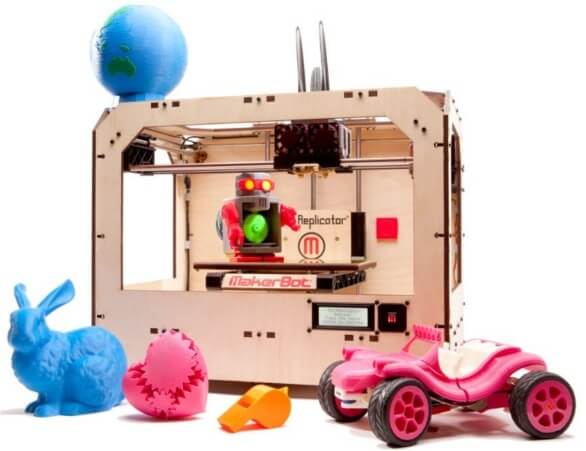

Three years ago they had three employees and were still trying to keep their equipment from breaking down. Now MakerBot employs 75, has millions in funding, and 7500+ of their printers in use. The Brooklyn-based company is the epitome of a successful tech startup, all the more remarkable because their devices are completely open source hardware – free for anyone to build or modify on their own. MakerBot hopes to continue their phenomenal growth of the past few years by starting off 2012 with a bang. They’ve just released the Replicator, a bigger and badder 3D printing bot that can produce almost anything out of hard plastic up to the size of about a loaf of bread. It can even use two colors at once. The winner of the Best Emerging Tech Award at the 2012 Consumer Electronics Show, the Replicator is just one of the many ways in which MakerBot is staying on top of the 3D printing world.

There are many different 3D printing companies out there. Most deal with the high-end of the market – producing models and prototypes for designers and engineers. MakerBot wants 3D printing accessible to everyone. Their printers are considerably cheaper than the competition (just $1099 for the Thing-o-Matic), fit on a desktop, and are relatively easy to use. The Replicator continues in that tradition, it costs a little more ($1749 or $1999) but is able to print much larger objects – up to 225x145x150mm (~9x 6 x 6 inches). That’s a printing volume of up to about 5 liters – probably the biggest consumer-level printer available, and definitely a huge volume for household use. The Replicator can also come with two extruders, allowing users to print in two different color plastics during the same build. Bre Pettis, one of the founders of MakerBot, introduces the Replicator in the video below, followed by a more detailed look at how one goes about printing something on their new MakerBot 3D printer:

http://www.youtube.com/watch?v=euZivv8ySyA

Alongside devices like the Replicator and Thing-o-Matic, MakerBot also has a hand in the software side of 3D printing. Before they ever sold a printer they created Thingiverse, the online depot for 3D digital designs. Users create virtual objects on their computers, upload them to Thingiverse, and thousands of other users all over the world can download the design and print it out. Pettis says that “Thingiverse is exploding” and to date has more than 15,000 “things”. That number is actually a few thousand larger if you include variations that users share to help improve designs. Exponentially growing, fun, and friendly, Thingiverse shows how the 3D printing community is thriving with every new printer sold.

According to Bre Pettis, 2012 should see that growth continue and even push into new arenas. Perhaps the biggest focus is on educational applications. Before he was a 3D printing guru, Pettis was a teacher for seven years, serving tours of duty in middle school art and K-5 classes. It’s no wonder then that MakerBot already has a pilot program in Brooklyn to see how such devices work in the classroom, and will likely expand such tests in the years ahead. MakerBot has a dedicated site for sharing 3D printing curriculum and the company regularly receives interest from buyers who wish to purchase a printer for a school. In 2012, MakerBot is definitely aiming to get more and better 3D printers in the hands of children. As Pettis puts it: “the Replicator is as perfect for the classroom as it is for industrial engineers.” Ten and eleven year olds excited by the fun of 3D printing will also be exposed to digital design, programming, and electronics. As children create and learn, they’ll be able to see their imaginations come to life with the alternating errors and glories that accompany such unrestricted exploration. Pettis says that 3D printing “let’s you fail in a really wonderful way”, and that is a sure-fire recipe for inspiring interest in science, technology, and engineering.

What else is in store for MakerBot in the future? Pettis foresees more competition arriving from new companies interested in marketing 3D printers directly to consumers. To stay ahead of the curve, MakerBot will “keep innovating…keep trying out stupid things until we can add something that works…it’s the pursuit of excellence that makes us satisfied.” Pettis likens the expanding 3D printer market to the smart phone industry, with MakerBot producing the high-end, versatile, and must-have devices that users will want even as competitors explore cheaper or more specialized options. To that end, 2012 will see improvements in MakerBot software, making it easier to use. Pettis says the company is also looking to hire 30 or so new employees, expanding the company by more than 25%. That bigger team should be able to deal with the growth in community that is sure to follow the Replicator’s ship out date in a few weeks.

Looking even farther into the future, Pettis sees some really wonderful possibilities for MakerBot and 3D printing in general. They’ve already worked with NASA on a polymer project (though it didn’t pan out) and Pettis would love to see a MakerBot device on the International Space Station, then eventually on the Moon and Mars. There may also be applications in the military, and other extreme environments. Really, there’s no limit to where a versatile and relatively small 3D printer could be applied, especially one that is open source hardware and backed by a growing community of designers/users. That community is only going to get bigger, better, and more creative as hundreds (if not thousands) of Replicators are bought in the months ahead.

[image and video credits: MakerBot Industries]

[source: MakerBot Industries, Bre Pettis]