3D-printed widgets are taking the medical world by storm. Polymer-based skull implants? Check. Doughnut-shaped Tylenol pills? Check. Totally rad-looking prosthetic arms with a $150 price tag? Check again.

These, and plenty other medical novelties, clearly illustrate the potential of 3D printing to radically change the biotech and pharmaceutical industry. With its extreme versatility and inherent ability to customize products, many experts believe that 3D printing will finally blow the field of affordable personalized medicine wide open. Yet so far it’s been mostly hope — and plenty of hype — with little sign that the radical technology might actually become a medical mainstay.

Until now.

Last week, the FDA approved the first 3D-printed prescription drug, essentially validating the technology as a new heavyweight player in big pharma. “This may be the first truly mass manufactured product made by 3D printing,” said Dr. Michael Cima, a professor at MIT who helped invent the pill-printing technology back in 1997, in an email to Singularity Hub. “It’s revolutionary.”

The printed pill, SPRITAM levetiracetam, is a drug that fights many kinds of epileptic seizures. The brainchild of a little-known Ohio-based company Aprecia, SPRITAM is essentially an old drug ingredient packaged into a brand new, more effective delivery system. Unlike current formulations of the same drug, SPRITAM immediately dissolves upon contact with water and bursts into effect — a property obviously beneficial when trying to curtail sudden-onset seizure episodes.

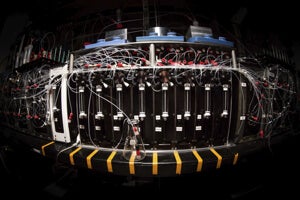

The secret to SPRITAM’s favorable kinetics is its porous structure. The pill is made with ZipDose, a powder-liquid 3D printing technology that stitches together layers of powdered medication into a porous, water-soluble matrix. With a sip of liquid, the matrix dissolves and releases the active drug ingredient for action.

There are other ways to make such tablets, said Cima, but they’re quite limited in dose since they require far more bonding agents. In contrast, according to Aprecia’s website, ZipDose can package up to 1,000 milligrams of drugs (the equivalent of two extra-strength Tylenols) into one nifty, easy-to-swallow pill.

No wonder Aprecia is excited. Founded in 2003, the company bought out MIT’s pill printing technology with the aim to boost the speed of printing to commercial production rates. Really, that’s the company’s main challenge and achievement, emphasized Cima. SPRITAM shows that manufacturing millions of parts simultaneously with a 3D printer is possible, and that’s revolutionary.

What it doesn’t represent is the dawn of personalized medicine, according to Cima.

Sure, “each tablet is essentially made one-at-a-time at very high speed by computer control,” says Cima, “that means it’s theoretically possible to tailor each tablet to the individual patient’s needs.” So doctors could have the option to adjust drug dosages on the fly. And if proper contamination controls are set in place, it may even be possible to pack a patient’s entire prescription into one pill that is manufactured at the pharmacy on demand. This would be especially helpful to seniors, who often have to remember to take multiple pills many times in a day.

All that’s certainly possible, but I’m just not sure how practical that would be in terms of cost, cautioned Cima.

Others are far more optimistic.

Lee Cronin, a chemist at the University of Glasgow who is building an all-in-one 3D pill printer (the “chemputer”) believes that in the future, patients will be able to download blueprints for drugs and print them at home. However, he concedes that personalized medicine isn’t the technology’s only goal. “Personalization is the ‘sexy’ driver but I think distribution and reach are the winners here — especially in the developing world,” he noted in the June 2015 issue of The Pharmaceutical Journal.

SPRITAM may be the first FDA-approved 3D-printed pill, but it certainly won’t be the last. Aprecia is working hard to implement ZipDose for other central nervous system drugs. Elsewhere, the pharmaceutical giant GlaxoSmithKline is running an early stage program to determine the feasibility of large-scale 3D printed pills using its own platform.

Many startups are also vying for a slice of the pill-printing pie.

FabRx, a small company founded by a team of researchers at the University of College London, is using 3D printing to manufacture pill shapes unobtainable through conventional production techniques. Their inspiration came from a study that showed that the rate of drug release depends on the pill’s surface area to volume ratio. A pyramid-shaped pill, for example, releases drugs slower than conventional round pills. This would be useful for extended release formulations and complement fast-dissolving drugs like SPRITAM. Eventually, the company hopes to 3D print a whole line of pills with varied absorption rates.

When asked about safety concerns in 3D pill printing, Cima cited dose uniformity. That is, companies will have to have quality systems in place to ensure that the labeled dose is actually in the product. “But then it’s not really any different from current manufacturing processes,” he added.

The real safety concerns — and a whole lot of legislative issues — come when 3D pill printers are finally cheap enough for DIY at-home use. Would the FDA be able to oversee personal pill printing? Should they? If an automated pill printer goes out of whack and misprints medication, would the blame fall on the machine’s manufacturers or the operators (i.e., the patients)? What if the machines were hacked? If people can reverse engineer patented drugs through 3D printing, how can those patents be protected? Will it be a detriment to drug development?

And — as Steven Kotler asked in Forbes — will people be able to hijack pill printers to manufacture illicit drugs?

It’s a new “Wild West” in the land of 3D-printed pharmaceuticals.

Banner Image Credit: Aprecia