Today, sewing relies on the low-tech power of human hands, but soon that may not be the case. Human workers are still needed for the final steps of making clothes, in order to align fabrics and correctly feed them into sewing machines. If robots could do that instead, shock waves of change would surely ripple through global supply chains and disrupt the lives of millions of low-wage earners in the developing world.

For better or worse, plenty of technologists, researchers, and companies are working on the challenge—but so far, getting robots to navigate the imprecisions of flimsy textile materials that easily bend has proven elusive.

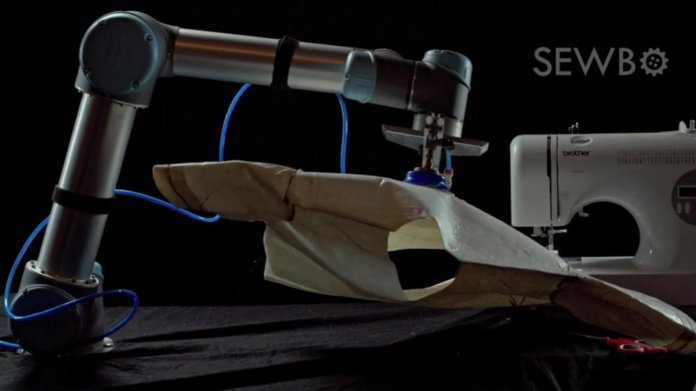

One promising solution, though, has come from an unlikely place: the sleepless brain of Jonathan Zornow, a young freelance web developer with no previous background in robotics, manufacturing, or the apparel business. His project, Sewbo, recently demonstrated the world’s first robotically sewn garment, and the inspiration came while watching a late-night Science Channel show called How It’s Made.

“I would watch How It’s Made to help me fall asleep at night, because I found it meditative and soothing to see the machines performing constant repetitive tasks,” Zornow told me. “In one episode they did blue jeans. In this case there were no machines doing serene repetitive motions. There were people involved every step along the way, and rather than help me fall asleep, it kept me up.”

It’s true that in almost every scene of the blue jeans episode, there’s the distinctive presence of human fingertips. Zornow got stuck asking why there weren’t robots there to perform the stitching, and what clicked for him while watching the show was the realization that getting robots to handle the complexities of a material that bends is difficult.

“The standard approach to robotic sewing has been to counter the complexity of working with fabrics, with equally complex machines.”

Robots are good at tasks that are precisely the same each time, but with clothing, the flimsiness adds a layer of complexity robots can’t yet handle.

The solution Zornow then came up with is almost laughably simple. Instead of pouring millions of dollars into fancier robots, he decided to find a way to stiffen the clothes in order to make them suitable for robotic machines.

“When I looked into it, it seemed that the standard approach to robotic sewing has been to counter the complexity of working with fabrics, with equally complex machines,” he told me. Instead, Zornow removed the complexity by making the fabrics stiff.

He decided to use a water-soluble polymer that washes out in warm water and can temporarily stiffen fabric, meaning the robot is handling a precisely-defined object when stitching the garment. The inspiration for that came to him while reading an article in Make Magazine that explored the water-soluble support structures for 3D printers.

To prove out the concept, Zornow rented an off-the-shelf robotic arm, which he used to demonstrate the approach. Then, last year, he formally announced the project as the first time a robot has been able to sew a garment. And he’s now pursuing the project full time to turn it into a business and was even invited to a robotics manufacturing consortium sponsored by the US Department of Defense.

The eye-catching part of Zornow’s breakthrough isn’t so much the technology used or the specific idea. Other promising high-tech solutions are being pursued and some have even tried, unsuccessfully, to automate sewing by stiffening clothes with starch.

What’s stunning is that since the 1980s, hundreds of millions of dollars have been spent trying to automate garment sewing, yet a single curious kid empowered by random ideas from the internet was able to address the challenge with a different (and relatively low-tech) approach. And beyond simply having the idea, Zornow had access to the robotic tools to actually pursue the concept, which due to cost would have been the stuff of dreams just a few years ago.

On display is a phenomenon entirely new in recent history, where big idea breakthroughs can come as much from individuals with access to the internet as from a heavily-funded research lab inside a government or corporation. It’s also an age where experts are being upended by radical outsiders, where leading biotechnology startups are being founded by aerospace engineers, and novice amateurs can routinely outperform experts in data science tasks.

In the age of the internet, we’re seeing the accelerating forces of ideas spread, and one where a single kid in Seattle can try to reshape a $1 trillion dollar global industry.

Whether Zornow’s solution will actually make meaningful headway into the apparel industry is uncertain, but ultimately his triumph is in showing that good ideas come from strange places.

Image Credit: Sewbo