How Flash Heating Plastic Waste Could Produce Green Hydrogen and Graphene

Share

Hydrogen could be a green fuel of the future, but at present it’s mainly made out of fossil fuels in a process that generates a lot of CO2. A new technique, however, generates hydrogen gas from plastic waste with no direct carbon emissions, while creating valuable graphene as a byproduct.

Batteries are currently the leading approach to decarbonizing transportation, but using hydrogen as a fuel still has considerable advantages. It has significantly higher energy density, which could give hydrogen-powered vehicles greater range, and refueling with hydrogen is much faster than recharging a battery. It’s also a promising fuel for heavy industries like steelmaking that can’t be easily electrified and could be useful for long-term energy storage.

Hydrogen’s green credentials depend heavily on how it’s produced though. Using electricity to split water into hydrogen and oxygen can be sustainable if powered by renewable energy. But the process is currently very expensive, and most hydrogen today is instead made by reacting methane from fossil fuels with steam, producing considerable amounts of CO2 as a byproduct.

A promising new process developed by researchers at Rice University generates hydrogen from plastic waste without directly emitting CO2. Of course, it too would need to be powered by renewable energy. But in addition to yielding hydrogen, the process also produces commercial-grade graphene as a byproduct, which can be sold to pay for the hydrogen production.

“We converted waste plastics—including mixed waste plastics that don’t have to be sorted by type or washed—into high-yield hydrogen gas and high-value graphene,” Kevin Wyss, who led the research while doing his PhD at Rice, said in a press release. “If the produced graphene is sold at only 5 percent of current market value—a 95 percent off sale—clean hydrogen could be produced for free.”

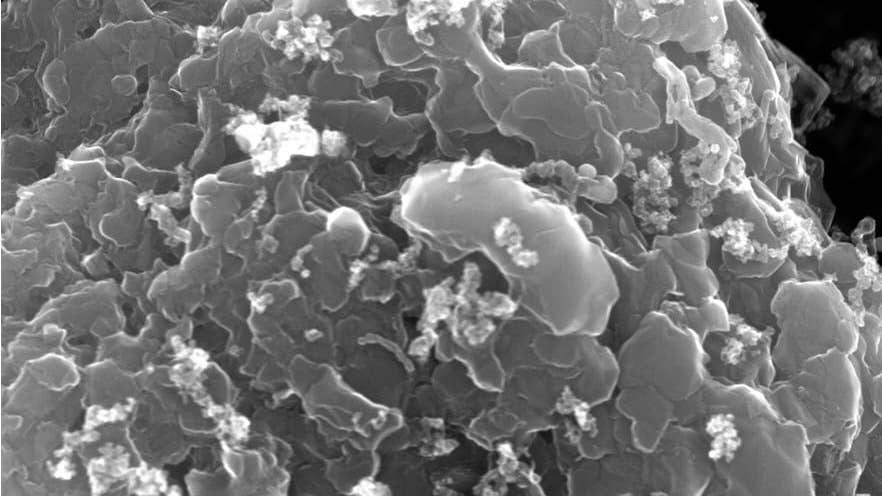

The new process relies on a technique known as flash joule heating, which was developed in the lab of Rice professor James Tour. It involves grinding plastic into confetti-size pieces, mixing it with a conductive material, placing it in a tube, and then passing a very high voltage through it. This heats the mixture to around 5,000 degrees Fahrenheit in just 4 seconds, causing the carbon atoms in the plastic to fuse together into graphene and releasing a mix of volatile gases.

The lab initially focused on using the technique to turn waste plastic into graphene, and Tour founded a startup called Universal Matter to commercialize the process. But after analyzing the composition of the vapor byproducts, the team realized they contained a significant amount of hydrogen gas with a purity as high as 94 percent. The results were published in a recent paper in Advanced Materials.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

By locking up all the plastic’s carbon in graphene, the approach produces hydrogen without releasing any CO2. And the economics are very attractive compared to other methods of producing green hydrogen—the feedstock is a waste product, and selling the graphene for even a fraction of the current market price essentially means the hydrogen is being produced for free.

Getting the process to work at an industrial scale will inevitably be challenging, Upul Wijayantha at Cranfield University in the UK, told New Scientist. “We don’t know, beyond the lab scale, what kind of challenges they will encounter when they handle a massive scale of plastics, gas mixtures and byproducts, like graphene,” he says.

Nonetheless, Tour is optimistic that the approach could be commercialized relatively quickly. “You could have a smaller-scale deployment for generating hydrogen certainly within five years,” he told New Scientist. “You could have a large-scale deployment within 10.”

If he’s right, the new technique could kill two birds with one stone—helping tackle plastic waste and producing green fuels all at once.

Image Credit: Layered stacks of flash graphene formed from plastic waste. (Kevin Wyss/Tour lab)

Related Articles

US Solar Surged 35% in 2025, Overtaking Hydro for the First Time

What the Rise of AI Scientists May Mean for Human Research

Meta Will Buy Startup’s Nuclear Fuel in Unusual Deal to Power AI Data Centers

What we’re reading