Need a new kidney? We’ll just take some of your blood and in about six weeks grow you a new one. That’s the promise of 3D bioprinting and one of the companies on the forefront of the technology just took a step closer to make it a reality. Organovo developed a research prototype of a bioprinter capable of producing very basic tissues like blood vessels. According to the recent press release, Invetech, Organovo’s strategic partner, will be providing the company with commercial versions of their device in 2010 to 2011. While it is still limited to simple tissue structures (full organs are a long ways off), Organovo plans to deliver the printers to various research institutions interested in organ and tissue production. Working with these institutions, Organovo hopes to one day progress to creating a system that can print organs as easily as other 3D printers print plastic figurines.

When it comes to bioprinting, Organovo isn’t the only name in the game. There are many other institutions trying to achieve the same goal (including Tengion whom we’ve mentioned before). There are differences in the way each company creates a scaffold for cells so that they hold together during printing. There are also differences in the way that cells are clustered together for printing. Essentially, however, no single approach to bioprinting has enough obvious advantages to make it a clear leader in the field. So we have something like the organ version of an arms race. Each company is struggling to produce viable tissues (typically blood vessels) and fine tune their machines as quickly as possible to be the first to see wide-scale adoption of their bioprinters as assistants in current human organ transplants. No one’s really made it there quite yet. But with a strategic alliance with Invetech, and commercial versions of their bioprinters, Organovo is making good progress.

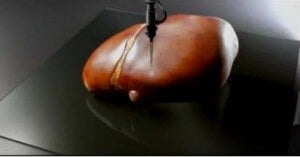

Organovo’s commercial version of the 3D bioprinter comes with some nice bells and whistles. There is a design software package that would allow tissue engineers to simulate their constructions before they are printed. Two different heads on the printer allow for the scaffold (or support matrix, or hydrogel) to be applied separately from the living cells. Those cells can even be printed with micron precision thanks to a laser guidance system on the device.

Yet as fancy as the printer may be, the real test for Organovo isn’t the machine, but what the machine produces. The blood vessels (and other tissues) that the 3D printer creates will have to be shown to function in living specimens over long periods of time, and be accepted and integrated into the host. That level of testing is still a long ways off for humans. So, we’re left with a really cool machine whose ultimate metric for its success isn’t yet available.

I don’t want to come off as too skeptical or too cynical about Organovo’s work. They’ve made some amazing progress so far, and the promises of 3D bioprinting are truly extraordinary. It’s simply too early to tell if the organs we print in the year 2030 will have a little stamp that says Organovo (or Tengion, or whoever). I do look forward to the animal tests that should be published in the next few years that will reveal the efficacy of bioprinted tissues to assist in transplants and other surgeries. Those results should give us a better indication of the future of this technology. Until then, keep up the good work Organovo. No matter who triumphs in the organ-printing arms race, it should be the organ transplant patients who arise as the real winners.