One day everything in space will be made in space, and this will radically increase the potential for human space exploration.

I recently read a novella that explores this very idea (see below for an excerpt). Cory Doctorow’s “The Man Who Sold The Moon” appears in Hieroglyph: Stories and Visions for a Better Future, an anthology of hopeful, ambitious, technically-grounded science fiction stories set in the near future. In the story, a small team takes on the daunting mission of launching a machine to the Moon that collects lunar regolith (moon dirt) and 3D prints structural housing panels for a future settlement.

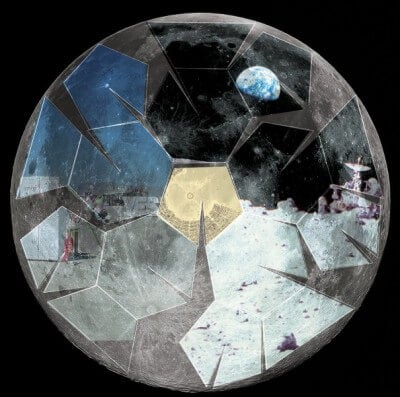

This idea is at the heart of a decades-old quest to create truly sustainable and Earth-independent space exploration. In the summer of 1980, a team at NASA Ames Research Center showed a simple set of machines could be sent to the lunar surface to mine resources and replicate themselves.

Earlier this year, in collaboration with NASA, my company, Made In Space became the first group to manufacture off planet Earth using the 3D printer we designed and built for use on the International Space Station. We are now able to email hardware to space by sending digital design files to the 3D printer. This reduces the need to launch everything from Earth.

Launching from Earth restrains what we can accomplish in space, due simply to the enormous amount of energy (and cost) needed to break free of Earth’s “gravity well.”

One future possibility is to launch machines that can transform space resources into the things that would have normally been launched. Doctorow’s machine turns moon dirt into housing structures. But similar machines may one day build other infrastructure to support humans on other worlds—from landing pads and roads to power supplies and rockets to get back home.

This is “living off the land” at its best, and it’s what will transform space exploration from a camping trip into more sustainable, long-term settlement.

Advances in robotics and teleoperation will allow these space manufacturing machines to be sent on missions well before humans arrive to use the structures they build. This idea of a robotic precursor mission to construct the human base will, in the end, reduce the overall risk and dangers of space exploration.

Doctorow emphasizes this point with an extended timeline between when his robot machine builds the housing panels on the Moon and when people would eventually travel there to use them. His use of a hyperbolic timescale, on the order of several generations before humans travel to the Moon, suggests that perhaps our society is not currently focused on the importance of exploration. It is a stark reminder of contemporary values and priorities—but surely not true for everyone.

Today there is a growing contingent of passionate, and in some cases well-funded, groups who have their eyes set on human space exploration beyond low-Earth orbit. I believe we will see people on the Moon once again in the next decade, and it will be achieved by privately funded groups.

Science fiction presents a variety of visions for the future, and Doctorow carries that torch.

He shows us a future for space exploration which frees us from our current Earth-dependent paradigm and is achievable with current technology by passionate individuals. However, like most science fiction turned reality, the practical technological solution will likely be different than the story.

The machines sent to the Moon in Doctorow’s story are inspired by Theo Jansen’s Strandbeest, a mechanical device that stores wind energy by pressurizing air bottles. Once the bottles accumulate sufficient pressure they begin articulating and moving the Strandbeest’s armatures. The Beast is alive!

We won’t have wind on the Moon, but we could possibly use other forms of energy transfer to pressurize tanks of gas to be used later for mechanical movement. With temperatures around 250 degrees Fahrenheit in the sun, you can imagine a machine on the Moon with matte black surfaces absorbing and storing solar radiation energy in pressurized gases.

But this is just one example of a potential problem solved. The fact remains that space is hard. Really, really hard.

That same device that sees 250 degrees Fahrenheit in the sun sees -250 degrees Fahrenheit in the shade. Solving that material and structures problem is still a challenge for engineers today. On top of that, lunar dust, which has never been smoothed down by winds like here on Earth, is so abrasive that it tears apart nearly any moving part it touches.

And the list of challenges goes on, from the fourteen-day, fourteen-night sun cycle to the impurity of the raw resources and the subsequent need to process them before utilizing them.

Even in the face of these challenges, teams working today are confident we can overcome them. “The Man Who Sold The Moon” is a testament to the idea that small, dedicated groups today have more power and resources than ever in history.

Building on the Moon is within reach, and worth pursuing. The frontier is never an easy place to go, yet it is where instinct leads us; this innate drive to push the limits, to do the seemingly impossible is at the core of every great human achievement.

“The Man Who Sold The Moon”

Cory Doctorow

Here’s a thing about 3D printing: it is exciting; then very, very boring; then it is exciting again. It’s borderline magic; when the print‐head starts to jerk and shunt to and fro, up and down, and the melting smell rises up off the build platform, and you can peer through that huge, crystal‐clear lens and see a precise form emerging. It’s amazing to watch a process by which an idea becomes a thing, untouched by human hands.

But it’s also s‐l‐o‐w. From the moment at which a recognizable object begins to take shape to the moment where it seems about ready to slide off, there is a long and dull interregnum in which minute changes gradually bring the shape to fruition. It’s like watching soil erosion (albeit in reverse).

This is the kind of process that begs for time‐lapse. and if you do go away and come back later to check in on things, and find your object in a near‐complete state, you inevitably find that, in fact, there are innumerable, mysterious passes to be made by the print‐head before the object is truly done‐done, and once again, you wish that life had a fast‐forward button.

But then, you hold the object, produced out of nothing and computers and light and dust, a clearly manufactured thing with the polygonal character of everything that comes out of a 3D‐modeling program, and once again—magic.

This is the cycle that the spectators at the inauguration of the Gadget went through, singly and in bunches, on that day. The Gadget performed exactly as intended—itself the most miraculous thing of the day!—business end floating on a stabilization bed as its legs clawed their way across the desert, and produced a single, interlocking shingle made of precision‐formed gypsum and silicon traces, a five‐millimeter, honeycombed double‐walled tile with snap‐fit edges all around.

“That’s what it does, huh?” Blight had been by to see it several times that day, alternating between the fabulous dullness of watching 3D paint dry and the excitement of the firing range, from which emanated a continuous pop‐pop‐pop of gleeful shooting. Someone had brought along a junker car on a trailer, covered in improvised armor, rigged for remote control. The junker had been lumbering around on the desert while the marksmen blasted away at its slowly disintegrating armor, raising loud cheers every time a hunk of its plating fell away, exposing the vulnerable, rusted chassis beneath.

“Well, yeah. One after another, all day long, so long as the sun is shining. We weren’t sure about the rate, but I’m thinking something like five per day in the summer sun, depending on the dust storms. It’ll take a couple hundred to build a decent‐sized yurt on labor day, and we should easily get that many by then.” I showed her how the tiles interlocked, and how, once locked, they stayed locked.

“It’s more of an igloo than a yurt,” she said.

“Technicality,” I said. “It’s neither of those things. It’s a 3D‐printed, human‐assembled temporary prefabricated experimental structure.”

“An igloo,” she said.

“Touché.”

Jason Dunn is cofounder and CTO of Made in Space, a space-based manufacturing company based in Mountain View, CA.

The excerpt above is taken from Cory Doctorow’s “The Man Who Sold the Moon”, a novella featured in Hieroglyph: Stories and Visions for a Better Future, edited by Ed Finn and Kathryn Cramer. Reprint permission from William Morrow/HarperCollins. Copyright © 2014 CorDoc-Co, Ltd. Released under a CC BY-NC 4.0 License.

Media Credit: NASA, Project Hieroglyph, Made in Space