So here’s a situation we’ve all been in. You just started a new company that builds and sells table top 3D printers. To save money, and be a badass, you use your 3D printers to make parts so you can build more 3D printers. Then, too late, you realize that you can’t keep up with your production schedule because your printer is too popular. Man, if I had a nickel…

Well, rather than encouraging others to point and laugh, Makerbot has decided to turn a problem into a cool opportunity for all of you do-it-yourselfers out there. A critical pulley is slowing down production, so Makerbot is asking owners of their 3D printers to create a few of these pulleys and get paid for their trouble. That’s right, Makerbot is introducing the world to crowdsourcing, a way of decentralizing production over a large set of independent individuals. Not satisfied with merely being open sourced and community minded, Makerbot is now seeking to turn customers into freelance builders.

We’ve been impressed with Makerbot since we started covering desktop 3D printers. Their Cupcake CNC, the first printer design, is fairly robust and is able to produce almost any shape you can draft that is less than 4″ x 4″x 6″. The plastic extrusion process is similar to industrial 3D printing techniques used by other companies. Check out an introduction to Makerbot’s CupCake CNC in the video from Rocketboom Tech after the break.

For those looking to make some quick cash, the Makerbot pulley proposal is probably not the way to go. Sure, the profits margins are high: each pulley will cost you around $0.11 in raw materials but will be purchased at $1 each (in sets of 30). The CupCake CNC costs $750, however. Making 840 pulleys, at 18 minutes a pop…yeah, you’re not going to break even quickly here.

But if you’re one of the 200 or so people who has already purchased a CupCake CNC, or if you were thinking of doing so anyway, this is a great opportunity. Not because of the money, certainly, but because of the possibilities that will arise if crowdsourcing succeeds. Bre Pettis, Zach Smith, and Adam Mayer, the powers that be at Makerbot, are hoping that this experiment in production will lead to more and more parts being crowdsourced. Eventually, as the capabilities of the CupCake CNC are improved, the entire product could be made in this fashion. A 3D printer that could print 3D printers has really been the goal all along.

Makerbot isn’t at the forefront of 3D printing, they can’t print stainless steel for instance, and their social networking model isn’t particularly innovative. Like other companies they have a blog, and a shared design gallery called the Thingiverse. What makes Makerbot so cool is that it’s 3D printing in your own home. I’m really excited that Pettis is leveraging what makes Makerbot unique: every time they sell a printer, they’ve created a manufacturer…maybe even a business partner.

Whether or not crowdsourcing works, we’ll eventually have self replicating desktop robots. It would be really amazing if those robots came from the DIY community, so I’m rooting for Makerbot’s pulley project to succeed. Unfortunately, I won’t be involved personally because my laser printer broke while trying to print $750 cash. Happens to everybody, right?

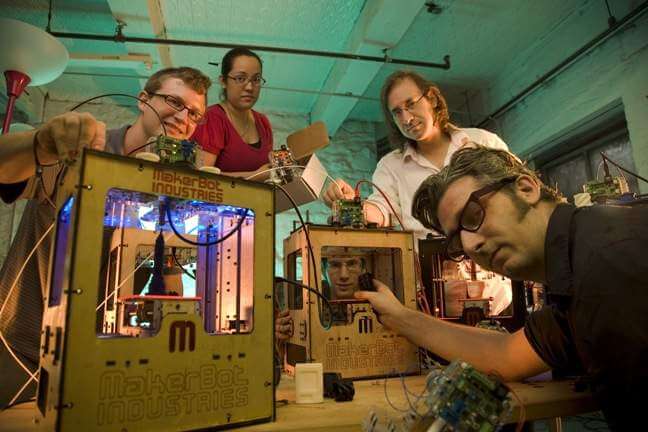

[photo credit: Crain’s New York]