5 Great Lessons on Scrappy Innovation for Big Companies Like GE

Share

Kevin Nolan, CTO of GE Appliances, spent 28 years at General Electric, “trying to do innovation,” as he puts it, before giving up. He finally accepted he couldn’t do it, internally at least.

At one point, Nolan watched how refrigerators were made and assembled at GE’s Appliance Park in Louisville, Kentucky and realized that the process of designing and building refrigerators today was not much different from the days of the icebox.

He wanted to infuse the company with some of the innovative techniques he was seeing others using. To do this, he created a new business within GE Appliances — FirstBuild — with the mission of inventing a whole new world of home appliances and infusing innovation into an industry that was lacking it.

FirstBuild focuses on bringing together a diverse community of enthusiasts, designers, engineers and makers to share ideas, test them and then build real products.

Here are five lessons (some new, some just good reminders) on scrappy innovation from Kevin Nolan’s talk at Singularity University’s Exponential Manufacturing Summit.

1) Create a Separate Environment for Risk and Open the Doors

FirstBuild’s offices are located a few miles away from GE’s Appliance Park on the University of Louisville's campus (part of the strategy is getting students involved). It’s important to note that this new venture is physically separate from the corporate offices — that’s one of the secrets of their success. Instead of asking people to sign non-disclosure agreements and go through strict security, everyone is welcome to come see what’s happening at FirstBuild.

“What we're doing at FirstBuild couldn't be more different [from the corporate office]. It's completely open. Anyone can come in any time. We're open 9 in the morning till 9 at night Monday through Friday, 9 AM till 5 PM on Saturday. If you're a competitor, if you're just someone that wants to see what we're doing, anyone can come in.”

2) Let The Community Validate Ideas

At FirstBuild, the engineers work alongside the community to execute projects. New products are built in small batches, using various manufacturing techniques. Those products are then sold just to validate the idea. If there’s a market for it — only then will they build more. As Nolan says, “That’s our real value add: to sell products to validate that people really like the innovation we're working on.”

The power of community is clear in everything that’s happening at FirstBuild — anyone can stop by the office and anyone can pitch ideas online. The community is the driver in this scenario — not executives and five-year business plans.

“The whole aspect of FirstBuild is not inside us, it's working with the community and doing everything with the community on how we design, build, and sell products and to build products that people are passionate about and that they really want.”

Idea voting on FirstBuild.com Check out the kitchen cabinet garden that automatically lights and waters vegetables and herbs!

3) Stay Agile and Make Small Bets

There are no three-year product roadmaps at FirstBuild. The rule of thumb is 6 months from idea to market. They aim to come out with 12 new products a year — with at least one of those graduating to the big leagues at GE Appliances, which means that the demand is so high, it needs to be built at scale.

“We're all about experimenting…We don't have a plan, which sounds odd from GE…We don't know what we're going to be working on during the year, because it iterates, it changes constantly. It's basically what the community wants to work on."

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

4) Run Community Hackathons Instead of Product Planning Meetings

Some of FirstBuild’s best successes have come out of a group of people having fun and just seeing what crazy (or not so crazy) ideas come out of it.

“Our best product planning has actually come out of hackathons. This is not how corporations typically do product planning, but our hackathons have just been amazing things. People coming in there, in 12 hours will come out with 10, 12 ideas. But what we find out is what resonates with the community. What do people like working on? We have no clue what's going to come out of these hackathons.”

5) Stay Lean

FirstBuild strives to have zero capital investment in new products. That means the first product they sell actually can have returns. They make small batches of product to validate the idea because most of the time, there's nothing else like it on the market.

“The other thing is we're all about lean. As we try to do this with zero capital investment, lean is our best friend. I've been studying lean for a long time at GE. I've never had lessons like I'm getting at FirstBuild on what lean is really about. We don't make parts until we get orders or we have a purpose for the product. Our workforce actually [is students] from University of Louisville. We bring in engineering students. It is an unbelievable training ground, and we're flexible. When the students are available is when we make products.”

Nolan admits there are some unique challenges — like how to handle intellectual property when the process is so collaborative. Still, FirstBuild is a great case study for big companies looking to infuse their organizations with more creative methods for innovation.

Image credit: Singularity University and Shutterstock.

Sveta writes about the intersection of biology and technology (and occasionally other things). She also enjoys long walks on the beach, being underwater and climbing rocks. You can follow her @svm118.

Related Articles

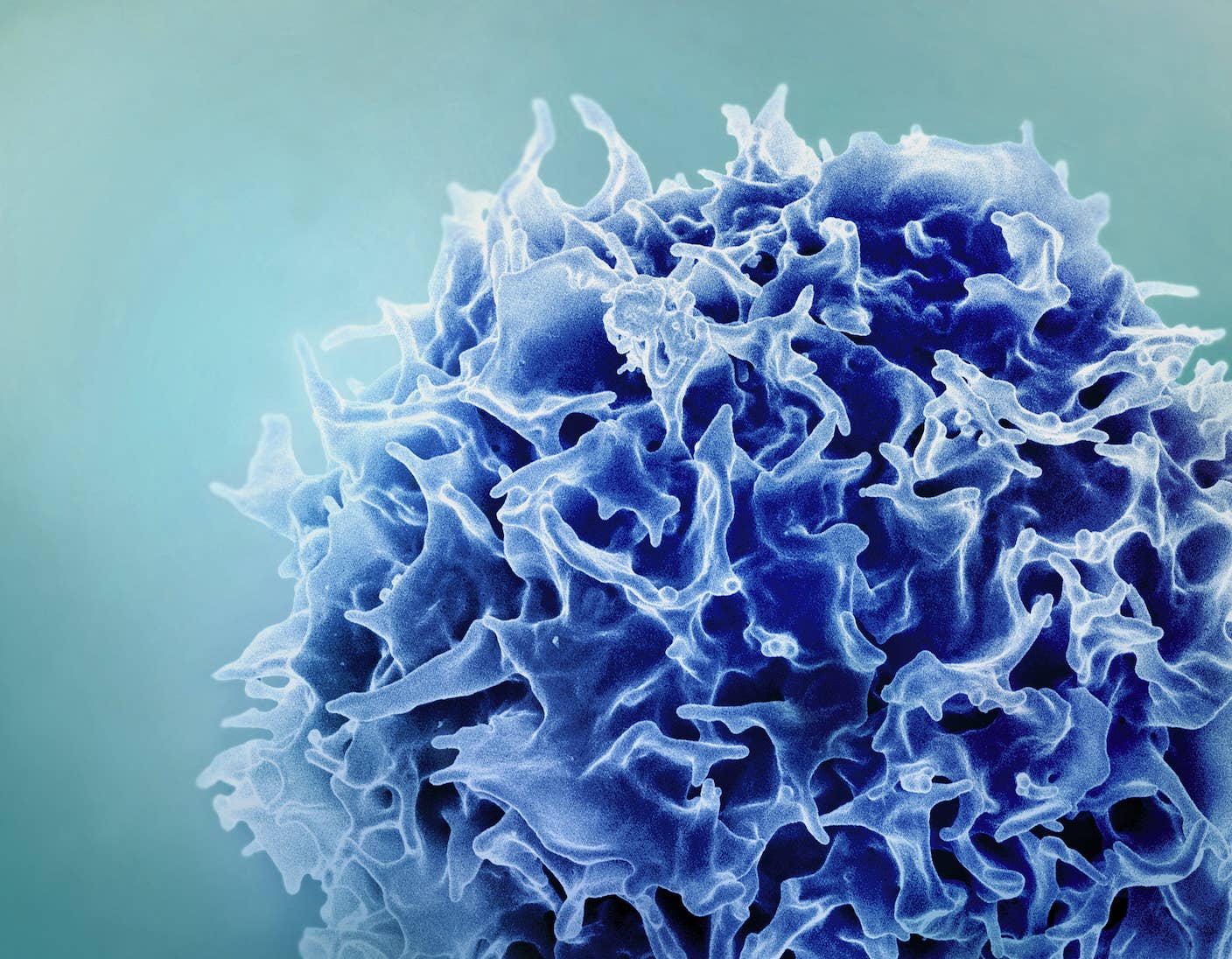

Single Injection Transforms the Immune System Into a Cancer-Killing Machine

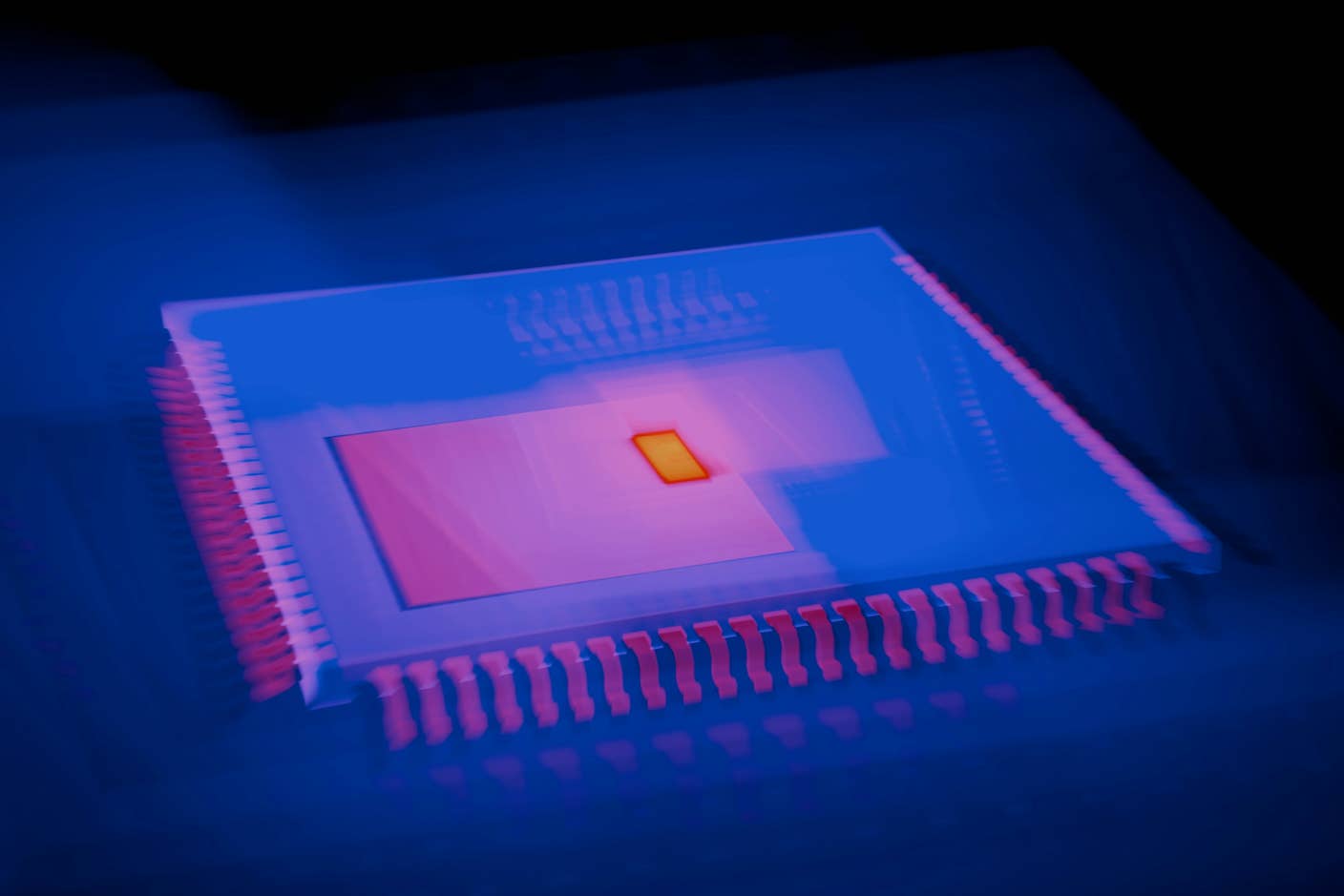

This Light-Powered AI Chip Is 100x Faster Than a Top Nvidia GPU

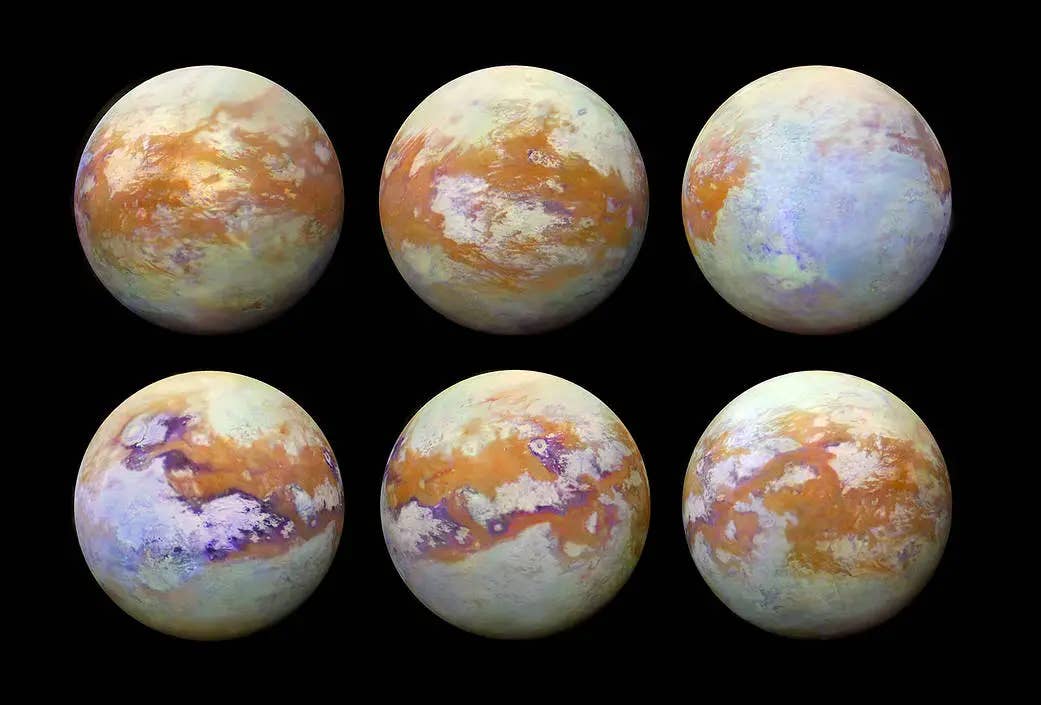

This Week’s Awesome Tech Stories From Around the Web (Through December 20)

What we’re reading