Human-Like ‘Bio-Skin’ Gives Robots a Much More Nuanced Sense of Touch

Share

In the middle of the night, when stumbling into the kitchen for a glass of water, I rely on touch. Even in the dark, my fingers can feel the handrails—alerting me to a flight of stairs—the walls, the curvature of the cabinet handles, and eventually, the glass.

We humans are highly visual creatures, but our skin has a sophisticated built-in system that lets us grab a cup of coffee, peel an overripe banana, or type on a keyboard without a second thought.

Part of this dexterity comes from a separation of powers: Some components in the skin detect direct forces from the outside world—for example, pressure or pinches. Others feel when the skin is stretched—like when you open your hand to grab an extra-large mug.

Now, a team from China and Singapore has recapitulated these qualities in artificial skin. Mimicking the division of labor, the three-dimensional electronic skin, dubbed 3DAE-Skin, adopts a skin-like multilayer construction.

Using microfabrication techniques, the team engineered a flexible device—roughly the size of the tip of a human thumb—that can sense different types of forces at a resolution similar to its human counterpart.

Combined with electrical circuits that acquire data and process it with a custom deep learning algorithm, the skin could tease apart tiny differences in touch. In one study, like a blindfolded but seasoned grocery shopper, it gauged the ripeness of multiple fruits with a squeeze or two and decided whether a croissant or cake was overly stale with a poke.

While charming, a robotic grocery shopper is hardly the goal. The strategy suggests that mimicking the human skin’s architecture is a promising way to make electronic components that “feel.”

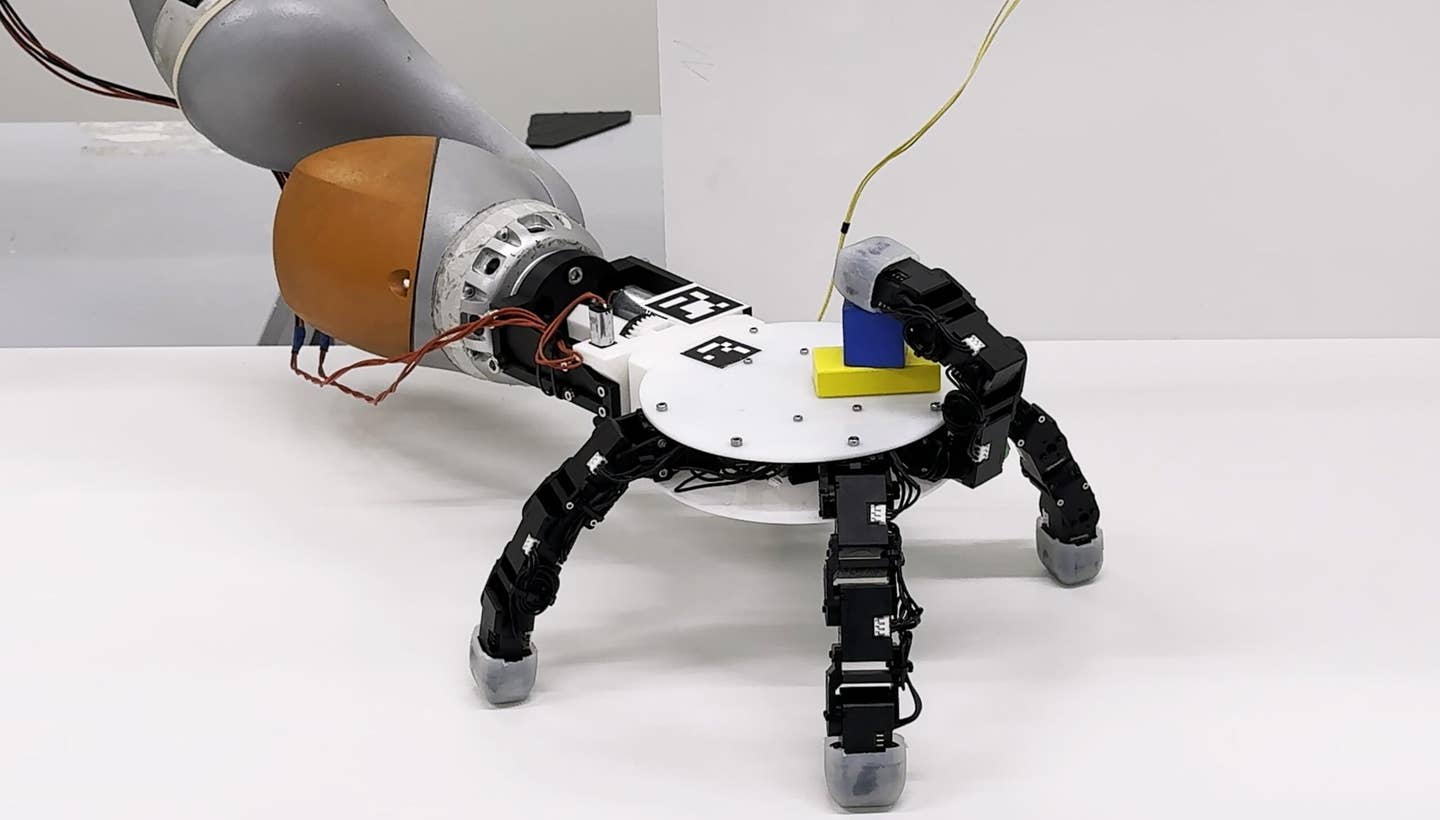

When embedded in robots or prosthetic hands, for example, the device could discern between different types of surfaces. And though it currently mimics fingertips, the skin could be used for other appendages or non-humanoid robotic systems, helping them navigate uneven terrain, for example, or in robot-assisted surgeries. The results were published in Science.

Three-Layer Cake

Our skin is the largest organ in the body, but outside skin care and the occasional scrapes, it’s often ignored.

But to bioengineers, the skin is a wonder. Every inch is heavily embedded with myriad sensors to measure temperature, pain, pressure, vibration, and stretch. There are six identified sensors specifically for touch, and they’re distributed across the skin in a clever way.

Unlike a crepe, the skin is more like a three-layer cake. Sprinkled across the top layers are sensors for temperature changes and different types of touch sensations. It makes sense: If you need to immediately move your hand from a hot pan or a needle prick, it’s better for these biological sensors to be closer to the surface. But top-layer skin cells constantly renew, and sensors too close to the surface face the risk of rapidly being eliminated.

A group of promising sensors are called Merkel cells, which sit between the top and middle layers and readily detect external forces like a prick or pinch. These cells translate mechanical data—pushes and pulls—into electrical pulses sent to the brain. With more processing, Merkel cells can create a general “feeling” of an object’s structure and overall texture.

Deeper down, but still in the skin’s middle layer, are sensors called Ruffini endings. These cells don’t care much for immediate touch sensations. Rather, they keep tabs on how much the skin stretches. For example, when flexing your hand into a claw, even when there aren’t any extraneous pokes that made you do that, you can still feel the strain of the skin thanks to these cells.

Both sensors are spread across the skin’s three-dimensional architecture. Imitating this setup could make it possible to develop an electronic artificial skin that feels both pokes and stretching at the same time, the team wrote in their paper.

Meet 3DAE-Skin

The artificial skin has three layers, with the thickness of each similar to its human counterpart.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

Most of the skin’s sensing components and electrical circuits are embedded between the top and middle layers. Force sensors act like Merkel cells, transferring immediate touch signals. Strain sensors, in contrast, resemble Ruffini endings and send stretch signals.

The completed artificial skin is made of individual units. Each has nine layers, with two force-sensing and two strain-sensing components and five “buffer” layers in between to stabilize them.

The team next sandwiched all this between two flexible layers of stretchy bio-compatible material. The device could withstand twists, pinches, and other skin deformations, and could sense pressure and strain like your average human skin.

Next came communications. The team added a data acquisition circuit, imprinted onto the surface layers, and a signal processing hub. The hub visualizes data from all 240 sensors in the device and deciphers different types of force and where they come from. The overall device is the size of the tip of a thumb.

Finally, the researchers developed an AI to translate the gathered data into predictions of touch. They trained the algorithm on a sample of 51 simple shapes—for example, a ball, a tube, or a piece of paper and how each reacts to pressure—does it maintain its shape or rapidly deform?

“When touching an object, human fingertips usually rely on” how it feels in order to infer the softness and shape of what we’re touching, explained the team in their paper.

While it sounds simple, it’s a tough calculation. Like squeezing an avocado to check if it’s ripe, you have to have an idea of how much to squeeze and when to stop.

After training on nearly 30,000 scenarios, the AI could predict the forces needed to grab an object—for example, an overripe banana. Like human fingertips, it could sense how much the object distorted its shape to fine-tune its grip.

In one test, the team hooked up a clamp-like probe equipped with the electronic skin and pressed unripe and ripe plums. The AI could readily discern between the two, even though the fruit looked relatively similar. In another test, a clamp easily detected a fresh bread roll from a tough, stale one.

Buying groceries is hardly the first use that comes to mind when building artificial skin. But the study shows that mimicking human skin’s biology, with a dose of AI, could lead to better artificial skin for robotics and prosthetics. These bioinspired 3D designs, combined with increasingly sophisticated microfabrication technologies, raises the bar for bio-compatible materials that match the resolution of the human skin for processing multiple senses.

Although 3DAE-Skin was developed to mimic fingertips, “the design and fabrication methods are scalable” and can be used for other types of prosthetic and robotic systems, the team wrote.

Image Credit: Tsinghua University

Dr. Shelly Xuelai Fan is a neuroscientist-turned-science-writer. She's fascinated with research about the brain, AI, longevity, biotech, and especially their intersection. As a digital nomad, she enjoys exploring new cultures, local foods, and the great outdoors.

Related Articles

This ‘Machine Eye’ Could Give Robots Superhuman Reflexes

This Robotic Hand Detaches and Skitters About Like Thing From ‘The Addams Family’

Waymo Closes in on Uber and Lyft Prices, as More Riders Say They Trust Robotaxis

What we’re reading