Chipotle’s New Robot Can Prep 25 Pounds of Avocados in Half the Time It Takes a Human

Share

Last year, fast-casual restaurant chain Chipotle brought in a new employee: Chippy the chip-making robot. Chippy was tasked with slicing corn tortillas into triangles, frying them, tossing them with lime juice and salt, and dividing them into portions. The bot must have done a pretty good job, because now the restaurant is bringing in one of its cousins: an avocado-prepping robot called Autocado.

Turning avocados into guacamole can be a tedious process. You have to slice the fruit open, remove its thin peel, and take out its pit. Then there’s the mashing and mixing in of other ingredients. Pretty doable for a batch of guac for two to four people, but less so when you up the final consumer count to, oh, 750,000 per day.

Chipotle restaurants have employees specifically dedicated to making guacamole, but it takes almost an hour to make one batch, and employees listed the task as one of the “less favorable” among other things they do at the restaurant.

"We are committed to exploring collaborative robotics to drive efficiencies and ease pain points for our employees,” said Curt Garner, Chipotle’s chief customer and technology officer. “The intensive labor of cutting, coring, and scooping avocados could be relieved with Autocado, but we still maintain the essential culinary experience of hand mashing and hand preparing the guacamole to our exacting standards.”

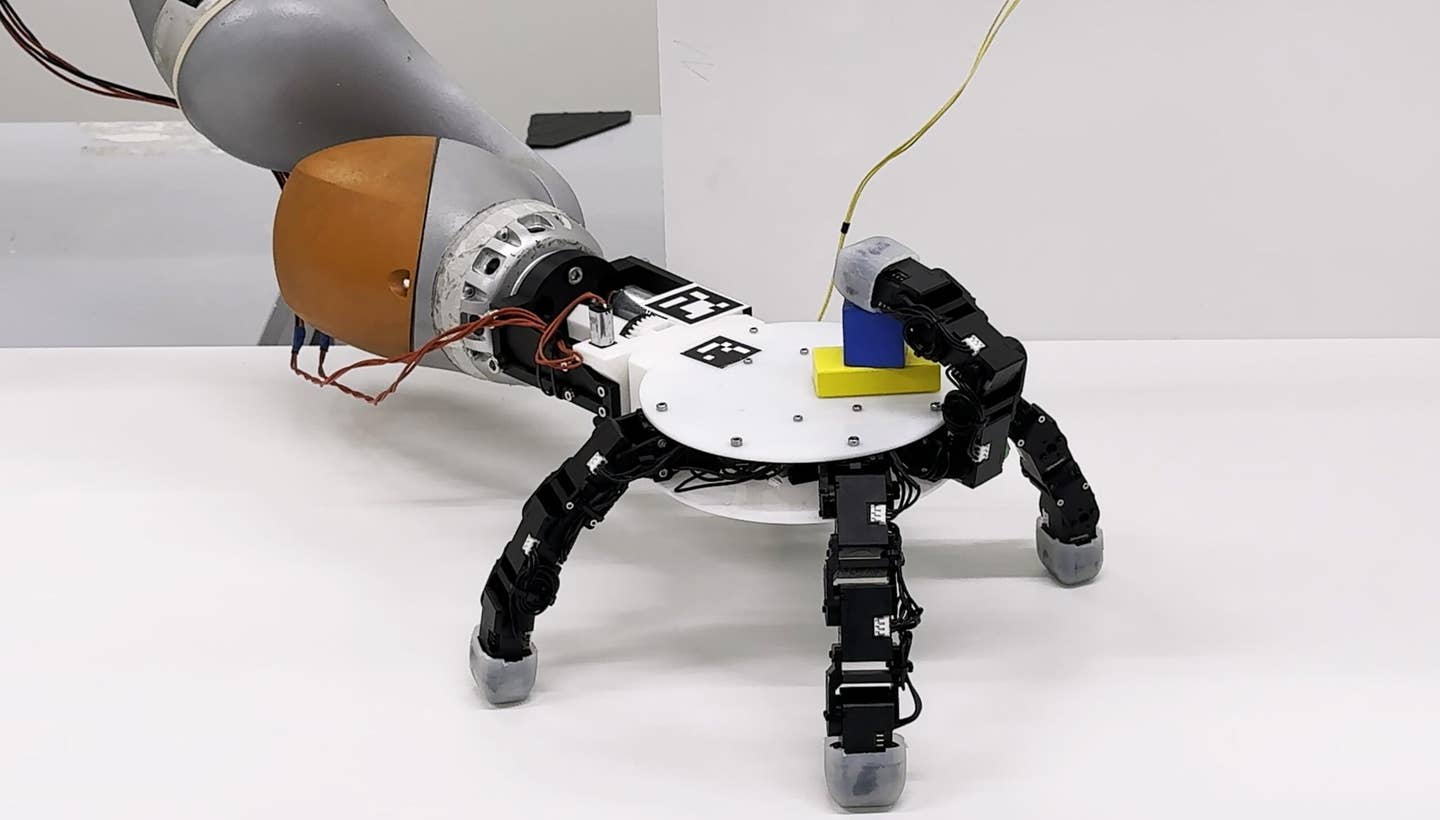

Autocado could reduce guacamole prep time by 50 percent. Here’s how it works. An employee empties a case of ripe avocados into the robot’s receiving drawer, which can hold up to 25 pounds of avocados at a time. The bot spins the avocados to a vertical orientation then transfers them to the processing device, where a blade slices them in half. Their pits and skin are removed, presumably by some sort of tongs or gripping device, and the fruit is deposited in a bowl. Once the bowl is full, an employee pulls it from the machine and moves it to the counter, where they mix in additional guacamole ingredients and mash the avocados by hand.

Be Part of the Future

Sign up to receive top stories about groundbreaking technologies and visionary thinkers from SingularityHub.

Autocado was custom-designed for Chipotle by California-based robotics company Vebu. The company says future versions of the robot will integrate machine learning and sensor fusion to evaluate the quality of the avocados, try to reduce waste, and make the cutting, coring, and peeling processes more efficient.

There’s been a shortage of labor in the fast food industry ever since the Covid-19 pandemic, and Chipotle is far from the first chain to bring in automated help. Miso Robotics’ burger-flipping robot Flippy is being used at CaliBurger and White Castle. Robots are making 45-second pizzas, and AI chatbots are taking drive-through orders.

Restaurants are likely to continue automating as much of their food prep and other processes as they can, namely because of the associated cost reductions. Many of them say this won’t cause widespread layoffs, since they’re already short on human workers to begin with. And just as Autocado doesn’t totally eliminate the need for human help, many food service robots are actually “cobots,” meaning they’re made to collaborate with humans and free up some of the employees’ time to focus on other things.

The Autocado prototype will be tested at the Chipotle Cultivate Center in California, and if all goes well, the bot will eventually appear in restaurants across the country.

Image Credit: Chipotle

Vanessa has been writing about science and technology for eight years and was senior editor at SingularityHub. She's interested in biotechnology and genetic engineering, the nitty-gritty of the renewable energy transition, the roles technology and science play in geopolitics and international development, and countless other topics.

Related Articles

Thousands of Everyday Drone Pilots Are Making a Google Street View From Above

This ‘Machine Eye’ Could Give Robots Superhuman Reflexes

This Robotic Hand Detaches and Skitters About Like Thing From ‘The Addams Family’

What we’re reading